All categories

Intelligent Crane solutions

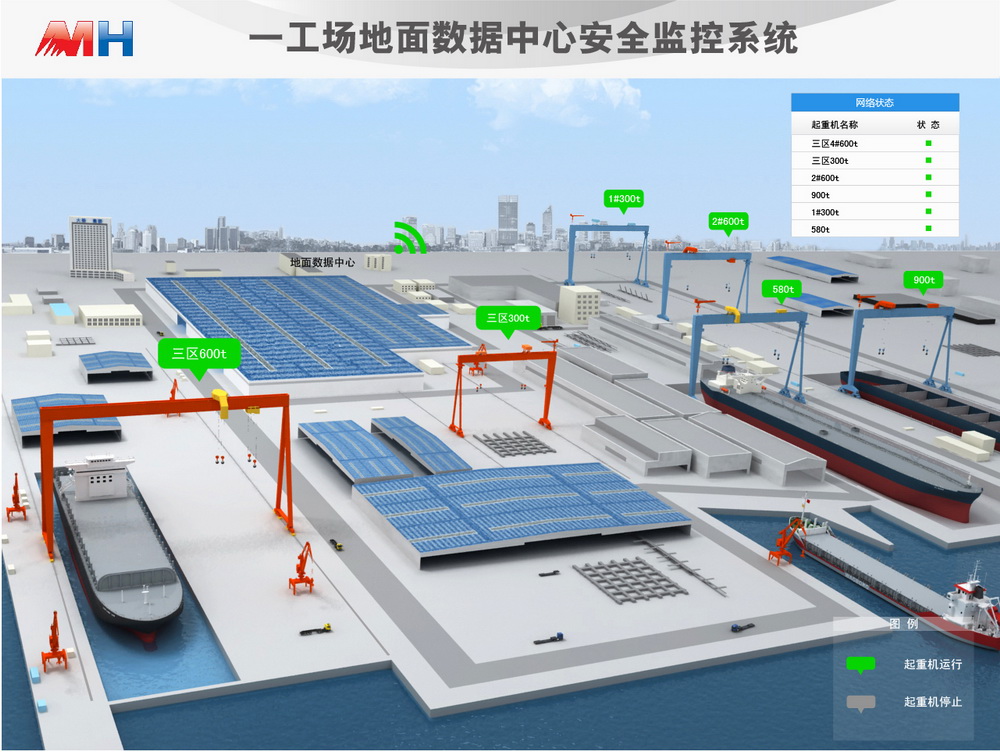

Safety monitoring system for shipbuilding gantry cranes

Case background

Shipbuilding gantry cranes areimportant lifting equipment used in large-scale structural section assembly and for the transfer and management of large electrical and mechanical equipment within a shipyard. During a repair or new construction project.

Shipyards have always focused on safety and work efficiency. The Country attaches great importance to the safety aspects of the cranes, and has introducedthe national standard GB/T 28264-2012 which requires that gantry cranesmust have asecure crane monitoring system.

Modern shipyard owners based on their own equipment management requirements and the need to meet the national safety standard have put forward the following requirements for a solution. MH-SCADA have risen to the challenge and have produced a product that matches and even exceeds these requirements:

l Have a secure operational monitoring ability, being able to achieve the real time monitor and recording of the operational data from ashipbuilding gantry crane. This to ensure the safety of people and equipment and toimprove production efficiency

l Have a system that offersrecording and analysis of all alarms with a view to being able to forecast the potential risk, to reduce the alarm rate, to ensure long term stable operation of equipment and ensure the safe operation of equipment and potential safety of operational staff

l A system that ensures systematic item check management that allows a more scientific approach to understanding the status. This leads to better maintenance regimes, improving crane reliability, spares management which in turn reduces downtime and improves overall availability and efficiency. A system that supports an expert analytical and data mining ability that supports fault analysis, understand difficult problems and offers rapid troubleshooting.

Case Study

According to the requirements of the shipyard industry, MH Company has usedthe MH-SCADA platform to develop a complete shipbuilding gantry crane safety monitoring, control and management system – MHCIMS (MH Crane Information Management System)

System composition

The MHCIMS system comprises of three parts.

l The crane maintenance station – installed in the cab and acts as the operator interface between the data centre and the driver. Using a modern open fieldbus all field data is communicated to the programmable logic controller within the maintenance station. These include the inverter drives, all sensors, video surveillance etc.

l The wireless network is the communications backbone between the maintenance station and the data centre

l The ground data center – gathers all the crane data, records the historical data, alarms and does the analysis for feedback to the operator.

Transmission

The main Ground Data Center receives all the crane maintenance data via the wireless network and is then available for viewing in real-time. The Ground data center is also connected to the shipyard Manfacturing Execution System (MES) through the wired network, and provides MES data feedback to the maintenance and asset management management. This allows continuous improvement to production efficiency

Features

Real-time monitoring and recording of historical data provides the critical base for future troubleshooting and accident recognition.

The system overview and real-time monitoring of each shipyard Gantry crane assists in finding equipment problems, positioning problems, reduces the trouble shooting time and adds to the safety of the equipment and personnel.

The alarm data management and analysis reports of all the shipbuilding gantry crane incidents helpsthe maintenance personnel to find fault reasons monitorfault trends making the system system maintenance friendly and convenient.

All the shipbuilding gantry crane maintenance work is managed electronically and helps equipment maintenance personnel to efficiently perform maintenance work. As it is all recorded managers have the ability to check the quality of the work performed and to manage the performance of the maintenenace staff.

The built in Fault Management expert system is designed to help asset management personnel to quickly find the cause of any problem and provides troubleshooting support and advice. This leads to shortened time to identify the problem and to ensure the safety of equipment. It also supports a user self-learning function helping managers and personell to effectively learn from past work work experience.

User benefits of MHCIMS

The MHCIMS shipbuilding gantry crane safety monitoring system helps users and managers to improve the safety level of the equipment operatio. In addition it assists in reducing the failure rate of equipment, improves the stability of equipment operation and guarantee the production efficiency of the shipbuilding business.

At the same time, the system also help customers to optimize the stock management of spare parts for the cranes and supporting equipment, improves the quality of the maintenenace work and ultimately reduces the production cost and leads to an overall improvement in overall operation.

Web Copyright:DALIAN MH ELECTRIC LTD. 辽ICP备05006725号-2 Powerby:300.cn dalian