All categories

Intelligent equipment remote monitoring solutions

Solution background

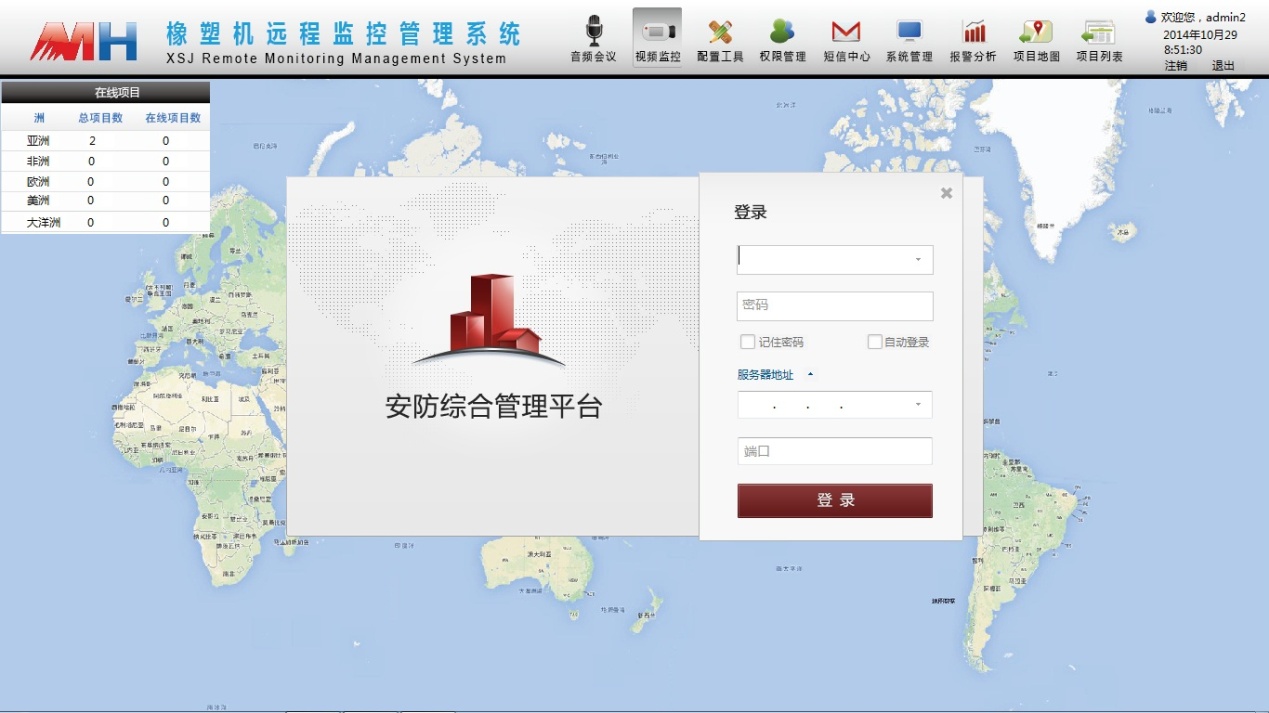

The MH-SCADA remote monitoring system uses an existing enterprise computer network, to monitor and manage customers on-site equipment operation. The solution allows manufacturers and OEM equipment suppliers to remotely monitor equipment status, to do remote fault diagnosis and management in order to offer world-class service and support. Through the remote monitoring solution, including to real-time monitoring and control, accurate knowledge of the machine data, machine operation gives a good base from which to effectively manage remote problems, improve efficiencies, deliver maintenance management and reduce the total cost of ownership for customers…leading to better sales.

Solution Architecture

Features

l The solution is a remote monitoring and control system, which consists of a monitoring and control configuration function, real-time data storage, alarm data query and analysis and system maintenance;

l The system can collect hundreds of sets of system parameters, electrical parameters, equipment operational status and important environmental parameters and so on;

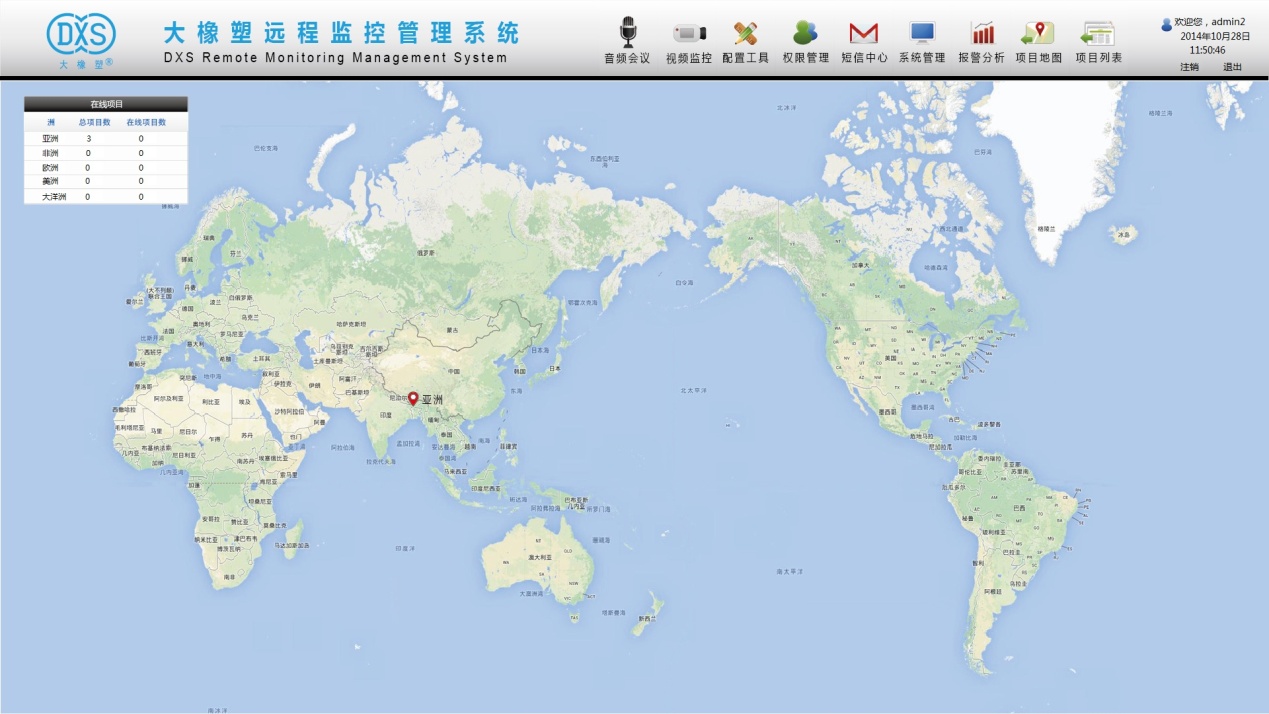

l Being GIS driven each region status can be dynamically displayed, showing if the region is healthy or if some equipment is in alarm. By drilling down into different sites it is possible to get higher detailed and higher resolution data from any sites equipment. This assists the central operations to manage and debug problems very quickly.;

l A real-time display of the alarms is available and the full alarm history is available for technical staff to do customized queries in order to improve trouble-shooting capability.;

l The alarm management module reports against international standards including EEMUA 191 and ISA 18.02. This allows customers to benchmark themselves against world-class standards.Which together with knowledge of the machine or process allows for continuous improvement of operations;

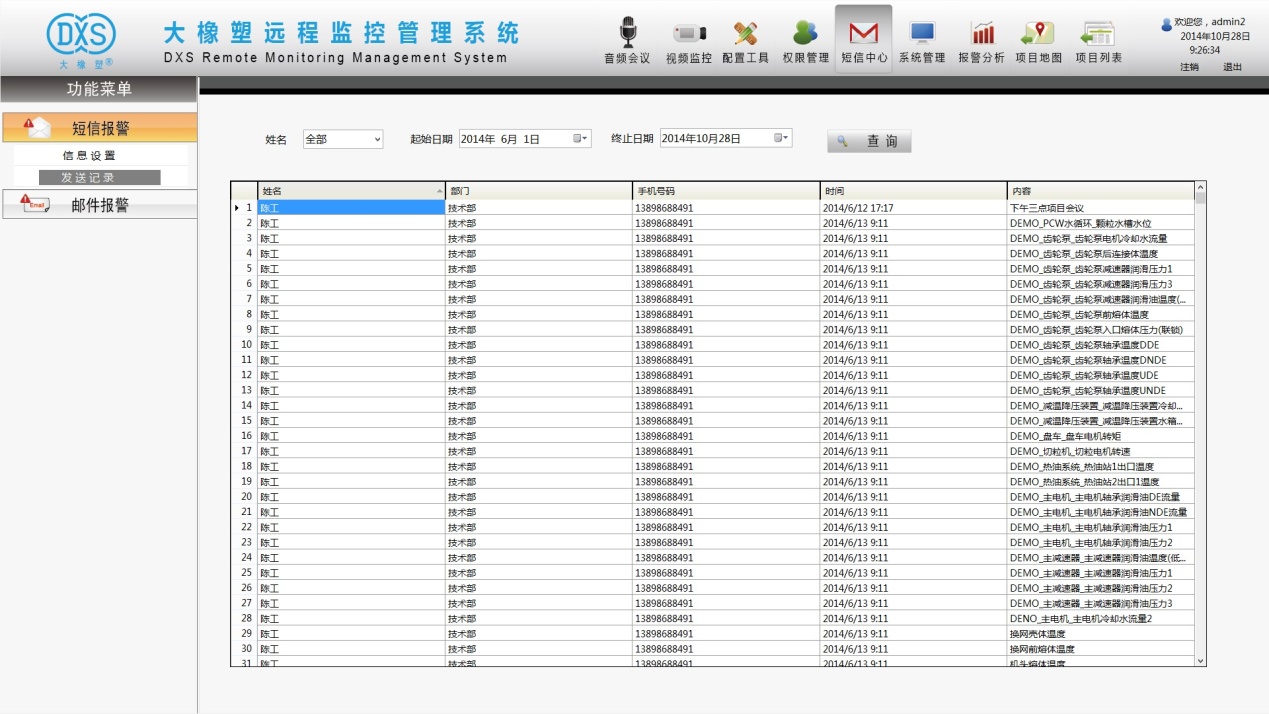

l Alarm and other information can be sent to people in the form of SMS or e-mail to send, it is also possible to send a custom message;

l On-site data is stored for a long time storage allowing process and technical specialists to use for process optimization;

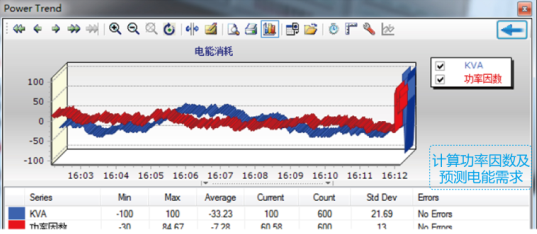

l The powerful reporting capability allows users to statistically analyse the key data such as equipment running time, energy consumption and production thereby providing valuable reference data for improving the equipment’s performance;

l To achieve more than one meeting (the application of smart phones and other devices) audio session function, recording audio and other functions, to achieve remote video surveillance, storage and other functions (Documasters…not sure what you are trying to say?);

l Viweing of data can be achieved from anywhere using WEB remote access to the production site. This gives the ability to do remote monitoring, fault diagnosis or even testing and commissioning of equipment;

Functions

Project search

The intuitive GIS interface allows a “layered” approach to using the system. Each Country, regions, state down to each site is accessed by simply clicking through each GIS marker. This offers and intuitive and easy to manage system.

Process monitoring

This function allows users to monitor the individual process in real-time, it also shows real-time status and process parameters. This might be electrical parameters such as power, or process parameters such as temperature, pressure, volume, speed or production. Each individual process also shows the current alarms information.

Historical data analysis

The system can be queried and any historical data displayed on the trend curves. It is also then possible to export the extracted data for further analysis.

Real-time alarms and historical alarms

The system can display the current alarms and log all the alarms in a historical database. Users can then extract and query this database with custom user defined queries.

SMS and e-mail management

It is possible to send text messages via SMS to selected staff responsible for maintenance. It can also be setup so that should a response not be received from users that the alarm will be escalated ensuring that critical problems can be dealt with timeously. This ensures better productivity by decreasing downtime through a more pro-active approach to remote management of equipment.

Alarm analysis

Using the system alarm management and analysis tools allows users to better understand the alarms happening over time. Through categorization it is possible to report on alarms by frequency, time, duration, type and location. Analyzing and reporting on cumulative stoppages by alarm type allows a very definite outcomes approach to remote management as specific problems can be identified and addressed to improve the alarm rate and improve the overall effectiveness of the process or equipment being monitored.

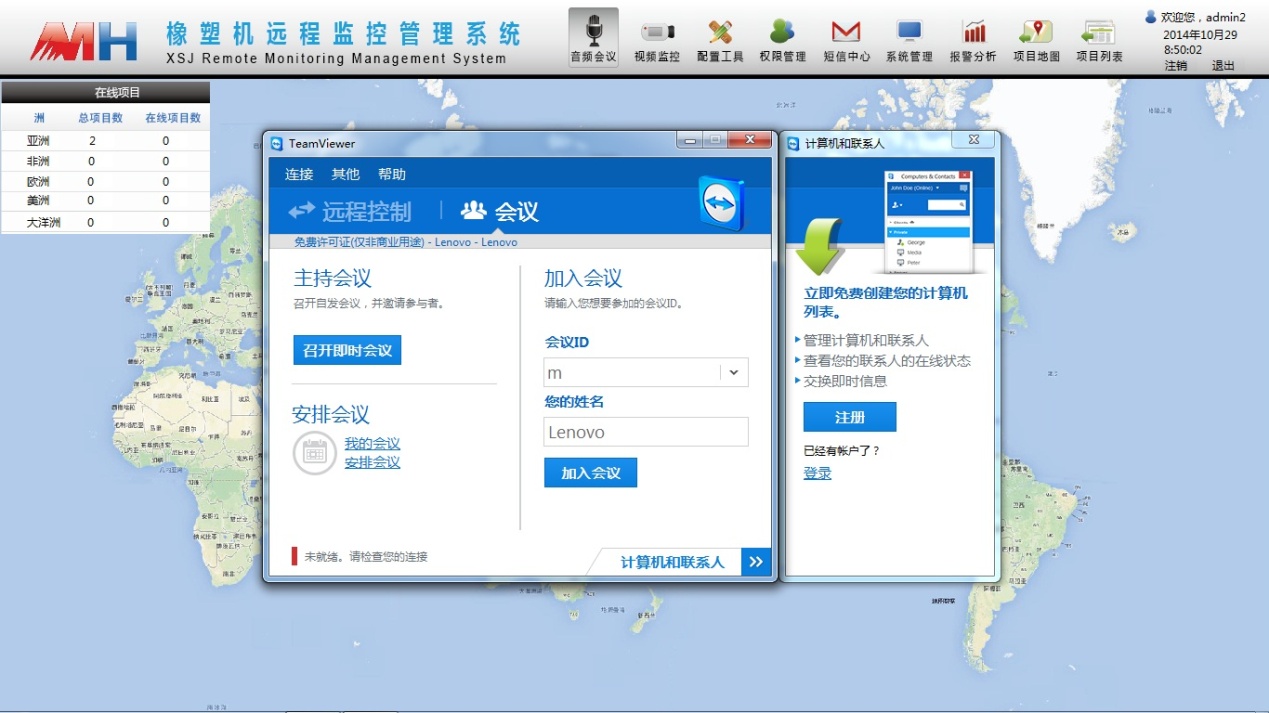

Multiparty Conference

Through the remote conferencing software to it is possible to engage in multi-user remote audio conferencing. The conferencing software allows real-time audio and video, document and desktop sharing, white-boarding, in order for various interested and specialist parties to communicate effectively with a view to continuously share information and improve a system.

Video surveillance

Through the integrated security management platform software it is possible to do remote video surveillance of a site. It is also possible to review historical video footage that can assist with a better understanding of a situation. It will also assist in be able to judge the cause of the failure and to be able to provide accurate maintenance advice.

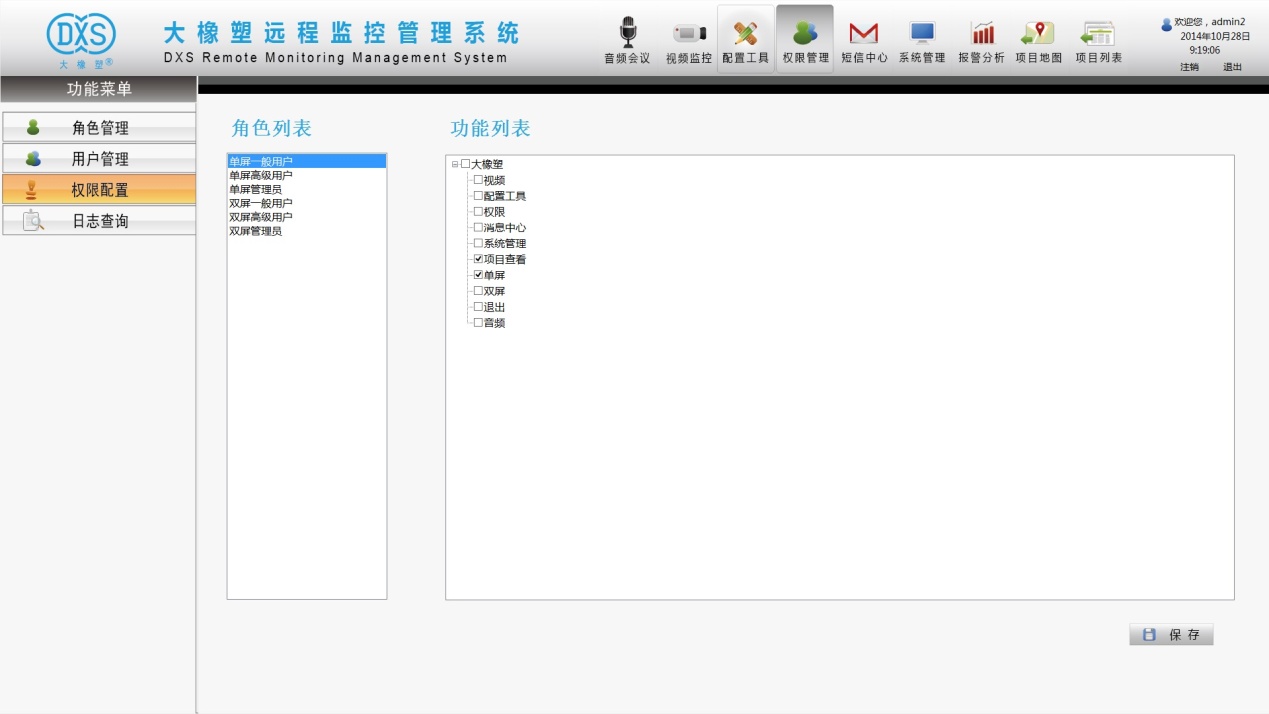

User rights management

This system function can assist in building a secure and role based application and allows users to setup; role management, user management, permissions configuration and other functions. One of the roles of the authority to set the level of membership, user management for editing user information, permissions configuration for setting the access permissions for each level of authority, log query for the user to query the operation record.

Mobile terminal

The system supports communication through mobile phone text messages, This means the efficient communication of job management information, alarm information and the remote assignments of tasks all lead to an improved and more efficient operation.

User benefits

The Intelligent remote service management system successfully meets the demand of a centralized monitoring and equipment management system. It also ensures the close communication between suppliers and their customers. It also ensures timely responses to customer feedback, improves service capability and levels. Leading to reduced maintenance costs and improvedefficiency of maintenance.

In addition it is possible to extend the capability of the system towards further improvements through using the integration platform to offer further reporting and analysis of process, alarm and other data to enhance management decision making. This offers a capability to improve an equipment’s or process efficiency, reduce maintenance costs, safety and ultimately product sales through best-in-class support for machine builders.

Web Copyright:DALIAN MH ELECTRIC LTD. 辽ICP备05006725号-2 Powerby:300.cn dalian