All categories

Hoisting and conveying machinery automation

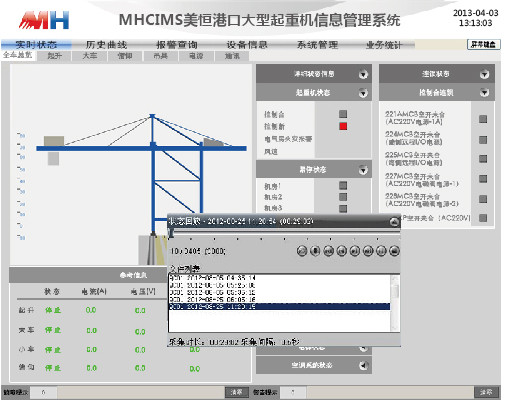

MH Crane Information Management Systems (MHCIMS) for Large Port Cranes

Summary

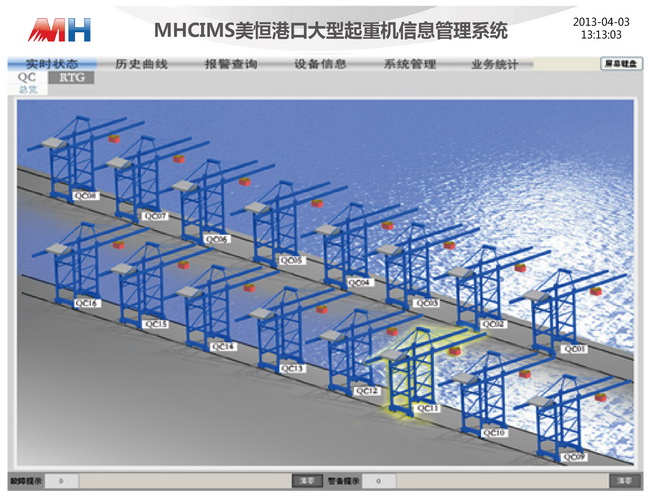

Based on years of crane industry management experience, MH has developed the MHCIMS information management system for large Port cranes. Besides using a modern and intuitive operator display showing the field operating condition and equipment management information, it also offers full equipment fault and alarm functions backed with diagnostic information. This feature makes it easier for operators and maintenance staff to observe and analyze a cranes operation. The historical trend and line Chart tool provides easy visualization of any crane information history.. MHCIMS offers two separate functions being crane operations and network management. It also offers many advantages over our competitors – such as as the modern visual display, reliability, easy operation and low-cost. So MHCIMS is one of the best choices for you.

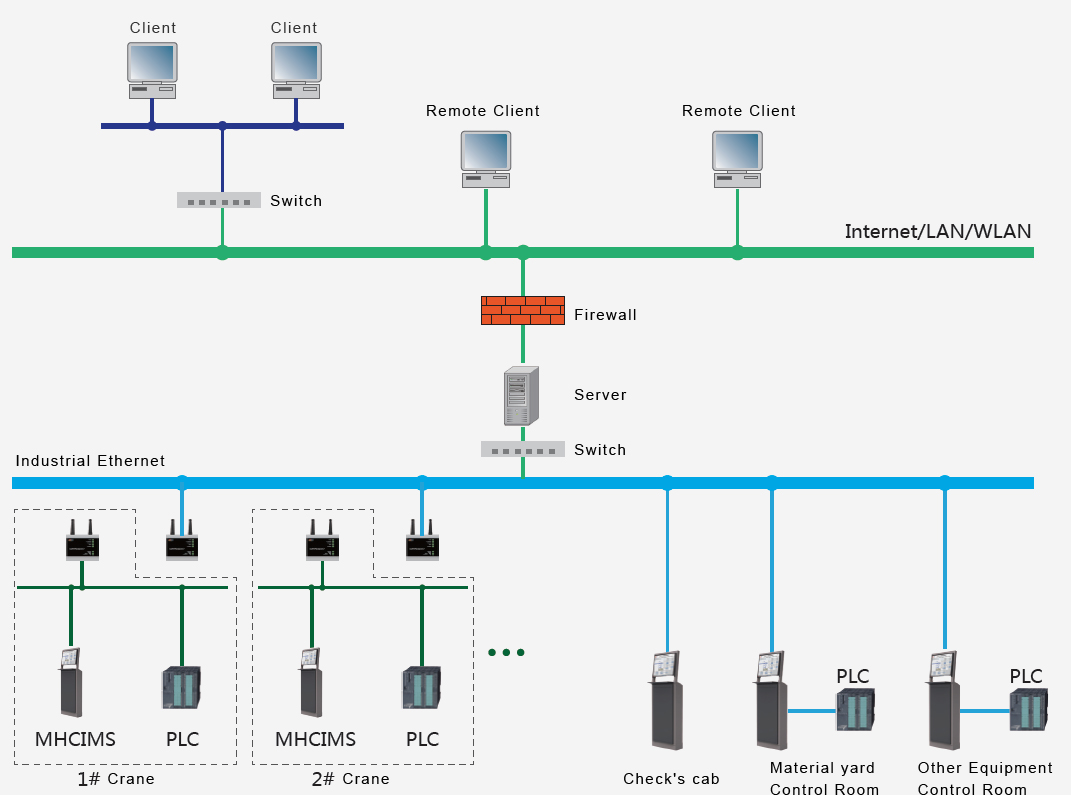

Network Architecture

The MHCIMS system developed by MH-SCADA, is available for different network architectures including local stand-alone design to a fully distributed architecture supporting a network of cranes. It is also possible to easily expand a stand-alone solution to a fully distributed one at low cost.

The MHCIMS network is divided into three distinct parts.. They are MHCIMS local workstation, MHCIMS central server and remote client (browser). All the real-time data, fault information, business, maintenance information that resides on the local station can be accessed and made available to remote view clients either on the operator application or through Internet Explorer.

MH-SCADA network architecture is based on a visual network programming framework, so it makes the interface not only intuitive but very user friendly. However the MHCIMS solution is secure, scalable, easy to use and very reliable.

Network architecture diagrams

Main Functions

Distributed Management:The MHCIMS Remote client can view the data from all of the cranes directly., including the real-time running state, historical data and alarm information.

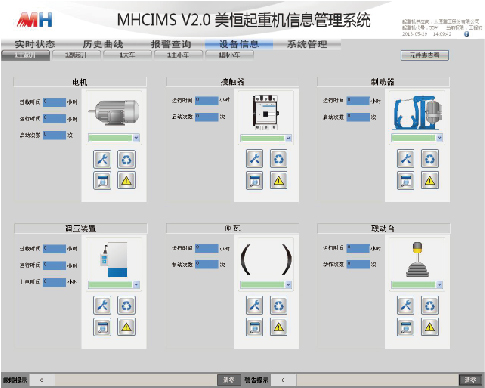

The following diagrams offer some example of the typical views available to the operators and management.

Equipmentinformation management

The system supports analysis and statisticsof important operational information such as equipment runtime and the number of operations, such as lifting cycles etc. It has warning management system whose warning value can be customized. In addition, the system provides recording management and query of equipment information.

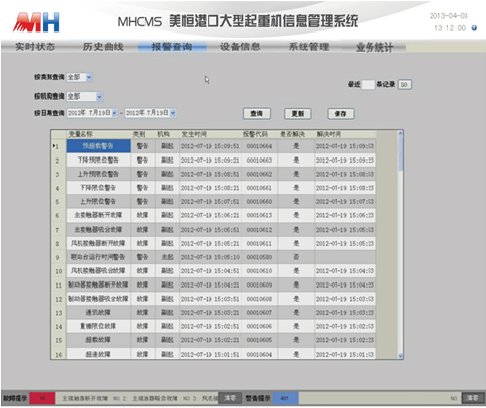

Alarm query and fault analysis

The MHCIMS system supports the ability to make data querying on the historical data and interrogating the PLC program to locate the cause of a problem. In addition to be able to investigate fault information root cause analysis and historical alarm files,The advanced Alarm Management supports Alarm reports against world standards and all relevant statistics around alarms, it is also possible to export all this information to standard file types.

Real-time and Historical trend curves

MHCIMS supports real-time and historical trend charts, and users can build their own charts dynamically adding any variable within the system to these charts.

State replay

The system saves all the data about equipment in the operational process, so it can replay the historical data through the interfaceat any time.

Operation Statistics

The system supports and the querying of operational information by time and class, including the number of bins handled, bin size, maximum weight, total weight, running time, standing time and so on, and this query result can be stored and the results exported for further analysis.

File and User Access control

MHCIMS is a multi-user system and supports features such as a pure view only mode. This allows people to view the data but not change anything therefore decreasing operational risk. The same modes of security can be applied to any aspect of the MHCIMS System.

Expandable Functions

Port logistics management module

l Material Storage: after receiving the production order, or other storage instructions and the signal that materials has arrived, the system identifies and records amount of material and generates its transfer code automatically. The system then stores the material inthe correct location by crane according to the warehouse availability or storekeeper’s requirement. The final location along with the identification is then recorded to the database.

l Material Dispatch: After receiving the production order, or other material dispatch instruction the system automatically generates a dispatch code and issuesthe relevant instructions to the e operator interface on the crane.

l Stock Management: Instead of manual stock management, the MHCIMS system records the transfer of material whether inbound or outbound.

l Material classification management: the system maintains a virtual warehouse, giving the operations and management a full view of where material is within the storage facility.

l Inventory Management: With the feature users can check availability of stock within the warehouse at any time. Inventory reports and documents are available in real-time making management very easy

l Inventory high limit alarm: The system will alarm when the inventory is less than the specific required value, assisting in minimizing out of stock problems.

Report forming module

l Inventory report,storage report and outbound report are generated automatically at the end of month, quarter or year. Moreover, users can customise the reports to give them the statistics they require.

Query functions

l Material storage query: MHCIMS supports many standardized queries and reports including dispatch or outbound queries, Goods Received, individual or single material item query and general inventory query.

l Query results are based on multiple criteria, including material code, material number, date of storage or dispatch .

Material tracking query function

MH-SCADA canexchange data with ERP to assist ERP in material tracking query.

l Stores area image function

l Show and manage storehouse area image, while updating the image based upon the data processing of crane. (Documasters…not sure what you mean here)

In order to improve crane management efficiencythe port logistics management module manages material movemnets according to needs and circumstances, all movements can be exchanged with the Enterprise ERP System and ensures the reliable and efficient exchange of real-time operations with the business system.

Besides the MHCIMS information management system for large Port cranes, MH can also develop port cluster equipment management system based on an individual authorities needs.

Web Copyright:DALIAN MH ELECTRIC LTD. 辽ICP备05006725号-2 Powerby:300.cn dalian