Intelligent system solution shipbuilding

- Categories:Port and shipbuilding

- Author:

- Origin:

- Time of issue:2021-01-20 17:18

- Views:

(Summary description)

Intelligent system solution shipbuilding

(Summary description)

- Categories:Port and shipbuilding

- Author:

- Origin:

- Time of issue:2021-01-20 17:18

- Views:

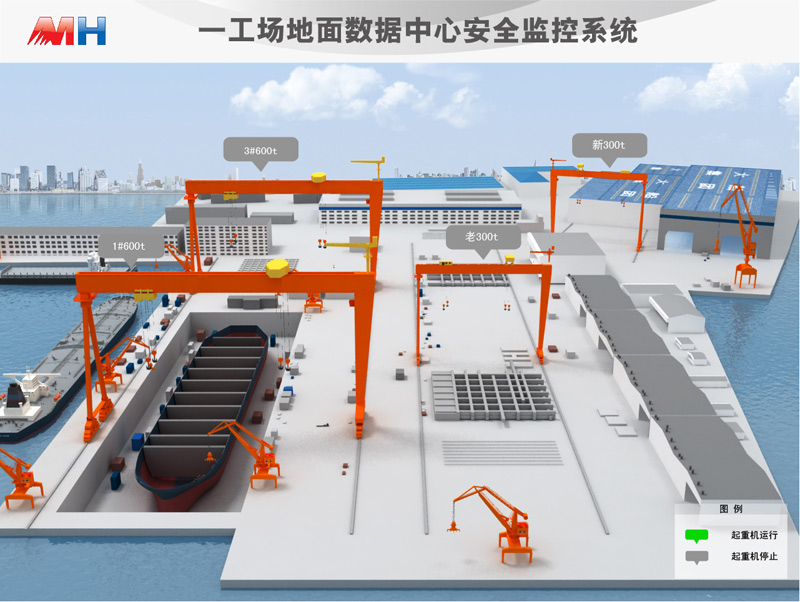

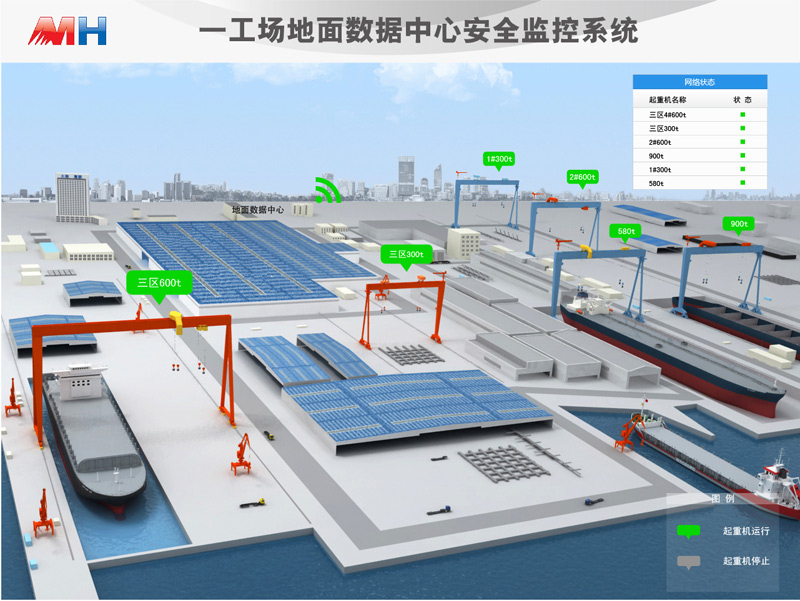

Safety monitoring data center of shipbuilding gantry crane

一、Case background

Shipbuilding gantry crane is an important lifting equipment used for the construction and assembly of large structural sections and the installation of mechanical and electrical equipment in shipyard and dock repair and shipbuilding. Due to the large tonnage and high accuracy of lifting, its safety and efficiency has always been the focus of shipyards. The state attaches great importance to the safety of cranes, and in the national standard GB / T 28264-2012, it is clearly proposed that cranes must have supporting safety monitoring system software. Shipyard owners put forward the following requirements for safety monitoring system based on their own equipment management and national standards

l The system has the function of safety monitoring, realizes the real-time monitoring and recording of the data of shipbuilding gantry crane, ensures the safety of equipment, and improves the production efficiency;

l The system has the function of alarm statistics, which can effectively predict the potential risk, reduce the alarm rate and ensure the long-term stable operation of the equipment;

l The system has the function of spot check management, which makes the equipment maintenance management more scientific, so that all departments can operate cooperatively and execute orderly, and improve the maintenance efficiency;

l The system has the function of expert diagnosis, which can effectively assist shipyard owners to solve difficult problems and quickly remove faults.

二、Case analysis

According to the needs of shipyard industry, meiheng company has built a domestic leading level safety monitoring system for shipbuilding gantry crane with mh-scada configuration development software as the core platform.

l system composition

The safety monitoring system of shipbuilding gantry crane is composed of crane maintenance station, wireless network and ground data center.

The crane maintenance station is installed in the cab. Through the connection of fieldbus and shipbuilding gantry crane control system, the data of inverter, PLC, sensor, video and other equipment are collected, recorded and analyzed in real time.

Mhrd series industrial radio station of meiheng company is used for wireless network to meet the requirements of long-distance transmission of shipyard.

The ground data center obtains the data of crane maintenance station through wireless network, and displays the operation status of each shipbuilding gantry crane in real time. The ground data center interacts with MES of shipyard through wired network to provide data basis for shipyard management and improve production efficiency.

l System features

Real time monitoring and recording plays a black box role in the key equipment data of shipbuilding gantry crane, and provides an important basis for future troubleshooting and accident identification.

By monitoring the operation status of all gantry cranes in shipyard, the equipment problems and positioning problems can be found in time, the troubleshooting time can be shortened, and the equipment safety can be guaranteed.

The alarm data of shipbuilding gantry crane is managed and analyzed to help equipment maintenance personnel summarize the key information such as frequent fault types, fault causes and fault trends, so as to make the system maintenance targeted.

The purpose is to realize the electronization of equipment maintenance work such as spot check plan, execution, audit, record and spare parts management of shipbuilding gantry crane, help equipment maintenance personnel to carry out spot check work efficiently, refine inventory management, and help managers to evaluate the quality and performance management of spot check work.

The built-in fault expert system helps equipment managers to quickly find fault causes and provide fault handling suggestions, so as to shorten the troubleshooting time and ensure equipment safety. At the same time, it also supports user self-learning function to help equipment managers effectively accumulate and inherit work experience.

三、Users benefit

Shipbuilding gantry crane safety monitoring system helps users improve the safety management level of equipment, reduce the failure rate of equipment, improve the stability of equipment operation, and ultimately ensure the production efficiency of shipbuilding business. At the same time, the system also helps customers improve the management of spare parts, optimize the inventory of spare parts, improve the quality of spot inspection work, and ultimately reduce the production cost and improve the level of equipment maintenance.

Product link:

Crane Division

MHCIMS

MH-SCADA

MHRDIndustrial radio

Web Copyright:DALIAN MH ELECTRIC LTD. 辽ICP备05006725号-2 Powerby:300.cn dalian