Intelligent system solutions

Here is the title one h1 placeholder text

- Product description

- Model specifications

- Product Features

- Other instructions

-

- Commodity name: Energy Management System Solutions

1. Background of the Plan

The energy consumption of manufacturing enterprises accounts for a high proportion of production costs. Different levels of equipment, process flows, product structures, and energy management levels have varying impacts on energy consumption. Utilizing information technology, energy efficiency diagnostics, and other technologies to build a centralized and unified enterprise energy management system is an effective way for manufacturing enterprises to improve energy-saving efficiency.

The enterprise energy management system should be a comprehensive platform based on the theoretical requirements of energy management system standards, integrating functions such as enterprise energy control. It includes real-time monitoring of energy usage, processing of energy-related matters, effective utilization of energy statistical data, energy efficiency evaluation, energy-saving diagnostics and improvements for equipment, processes, and the entire plant, energy balance and scheduling, energy forecasting, etc. This serves as the basis for high-level energy decision-making in enterprises. Under this platform, all matters related to enterprise energy management will be resolved, significantly enhancing work efficiency and production efficiency, while also saving energy and resources for the enterprise, reducing carbon emissions, and indirectly saving costs. Ultimately, it brings both economic and social benefits to the enterprise.

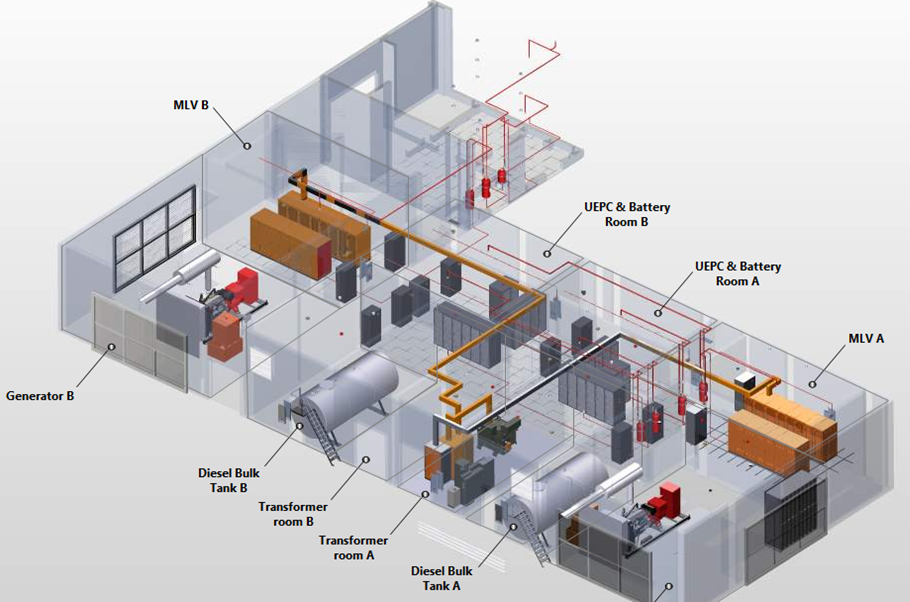

2. Architecture of the Plan

3. System Composition

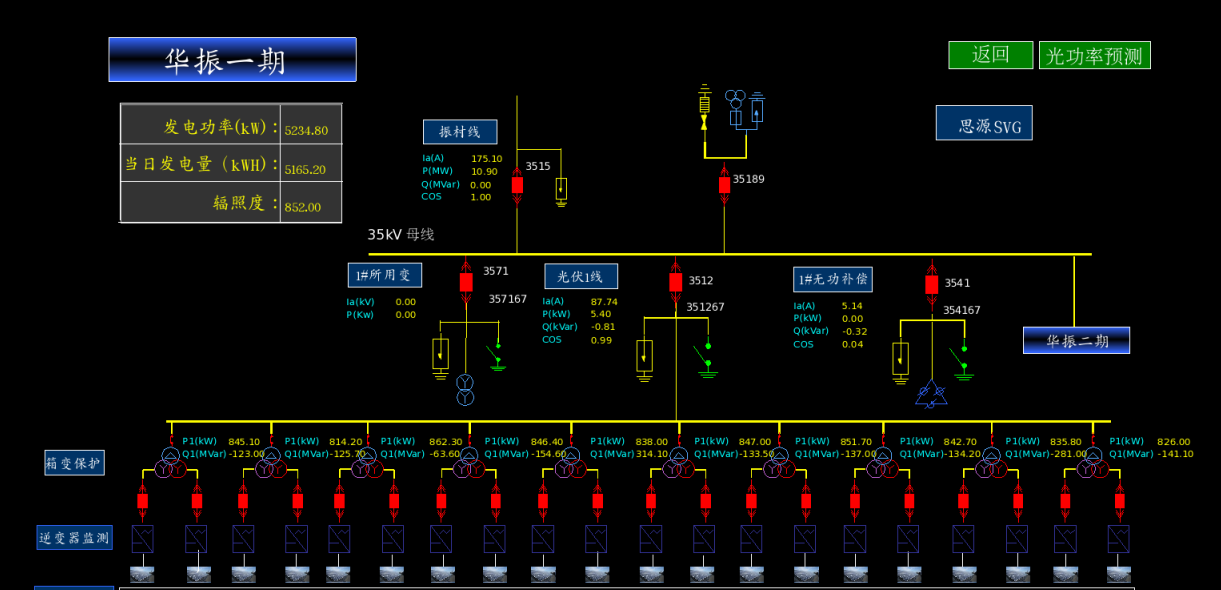

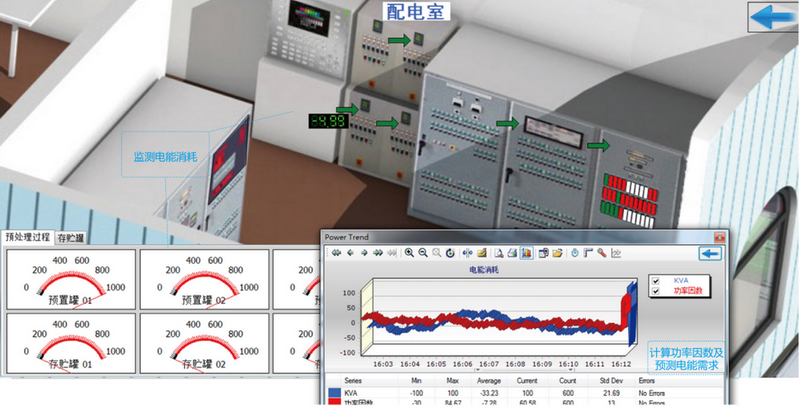

lComprehensive Energy Monitoring Module

lEnergy Networking Management Module

lEnergy Scheduling, Planning, and Management Module

lEnergy Equipment Management

lEnergy Load Forecasting Module

lEconomic Operation Module of Energy System

lBasic Energy Management and Environmental Protection Information Management Subsystem

4. Function Implementation

lComprehensive Energy Monitoring Module

The Comprehensive Energy Monitoring Module mainly collects energy operation parameters from various process segments, including but not limited to:

ØCurrent, voltage, power, etc. of the power system;

ØFlow, pressure, temperature, etc. of production gas;

ØFlow, pressure, etc. of production and domestic water;

ØAuxiliary systems, such as air conditioning systems, air compressor systems, and other important energy equipment.

The specific monitoring objects will be reflected in the energy collection point matrix list of the technical agreement, including areas, main processes, main equipment, equipment models, equipment quantities, detailed parameters of equipment, etc.

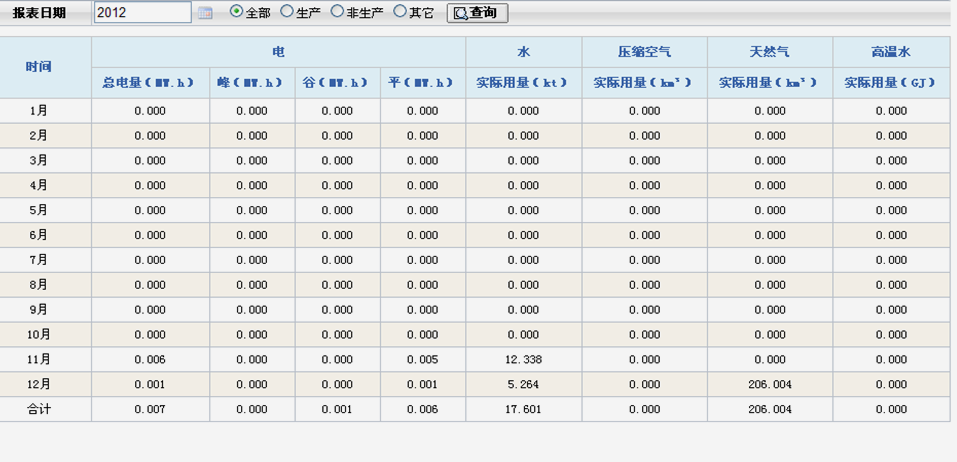

lEnergy Networking Management Module

ØCompany Energy Reports: Internal management reports, analysis reports, settlement reports, group company reports, and other customized reports;

ØEnergy Reports for Energy-Using Units: Production energy consumption reports, energy consumption comparison reports for the same period, equipment energy consumption quota reports, energy consumption analysis reports, etc.;

ØWorkshop and Team Reports: Operation reports, assessment reports, energy-saving control reports, etc.

Energy Reports: Automatically generated energy utilization status reports, energy-saving self-inspection reports, energy analysis reports, etc.

lEnergy Scheduling, Planning, and Management Module

Prepare energy supply and demand plans based on the actual energy data collected automatically by the system and manually entered, guiding the energy system to organize production according to the supply and demand plan, providing the required amount of energy to the main production line. The supply and demand plan is organized according to water, electricity, oil, gas (steam) media; collect and organize data on the actual occurrence, usage, and emission of each energy medium (natural gas), obtaining actual data on energy production operations, reflecting the production, distribution, and usage of various energy media, and managing and analyzing related energy consumption indicators.

lEnergy Equipment Management Module

This functional module can manage the energy-consuming equipment ledger of the enterprise, helping energy management personnel classify and manage key energy-consuming equipment, eliminated equipment, energy-saving equipment, etc., facilitating equipment information archiving and retrieval. Its functions mainly include:

ØEnterprise Equipment Ledger

Upload and maintain the enterprise equipment ledger.

ØKey Energy-Consuming Equipment Ledger

Upload and maintain the enterprise key energy-consuming equipment ledger.

ØIn-Use Motor Ledger

Upload and maintain the enterprise in-use motor ledger.

ØEliminated Equipment Ledger

Upload and maintain the ledger of equipment eliminated by the enterprise each year.

ØComparison of Eliminated Equipment

According to the list of backward and eliminated equipment published by the state, the system automatically checks whether the currently used equipment in the enterprise is backward or eliminated.

lEnergy Load Forecasting Module

Based on the energy consumption characteristics of the enterprise, establish an energy forecasting model. Predict the consumption of various energies (water, electricity, gas, etc.) for a certain future period based on product output or industrial total output value plans, and further predict product unit consumption and process energy consumption. The forecast results can also be analyzed. By predicting energy consumption in advance, it can help avoid tight or excessive energy inventory to a certain extent, indirectly helping enterprises reduce the risk of a broken capital chain.

lEconomic Operation Module of Energy System

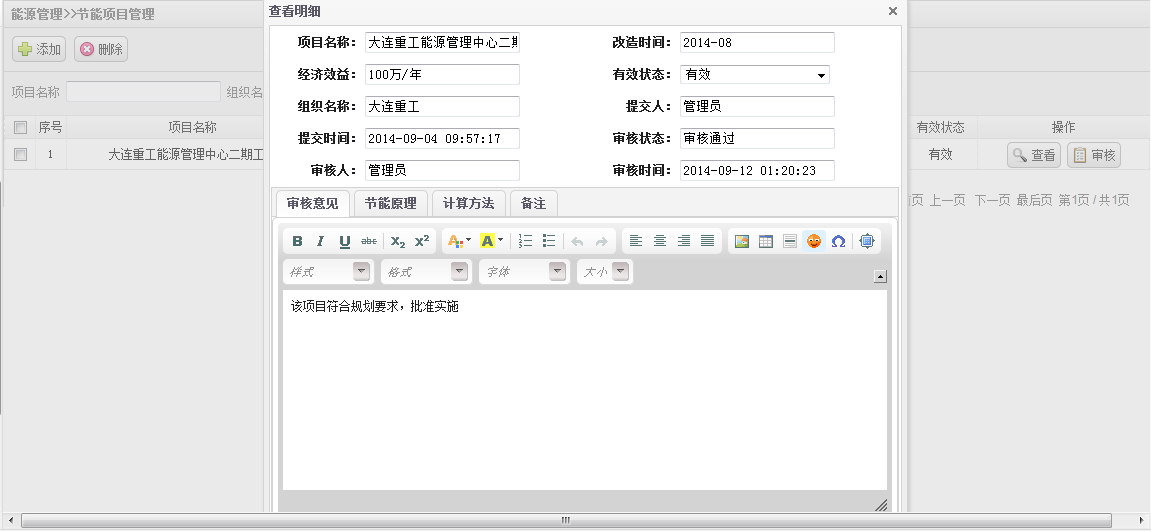

Manage the planning, approval, and archiving of energy-saving projects, and track the implementation progress of energy-saving projects. This facilitates the management of energy-saving technological transformation projects by the enterprise. By tracking the implementation progress of energy-saving projects, effective intervention can be made when the implementation deviates from the established goals; when energy-saving projects are completed, the actual energy-saving amount can be calculated to verify whether the energy-saving projects have achieved the expected results.

lBasic Energy Management and Environmental Protection Information Management Subsystem

Monitor and manage the quality indicators of energy media such as water, electricity, and natural gas, track and analyze various indicators, and issue timely alarms when the energy supply quality is abnormal. The application of energy supply quality management can prevent quality accidents and ensure the quality of energy supply.

The Energy-Saving and Environmental Protection Management Module mainly includes energy-saving amount audit and assessment, carbon emission analysis.

ØEnergy-Saving Amount Audit and Assessment

Provide enterprises with a quantitative tool for energy-saving amount audit and assessment, helping enterprises accurately reflect the effects of energy-saving measures.

ØCarbon Emission Analysis

By retrieving the physical quantities of various energy-saving measures from the database, calculate the carbon reduction amount, and then sum the carbon reduction amounts of various energies to obtain the total carbon reduction amount for the enterprise. The analysis of the enterprise's carbon emissions quantifies the social benefits brought by energy-saving and emission-reduction efforts.

5. User Benefits

By using smart instruments, PLCs, RTUs, and other automated hardware devices, the labor costs of energy collection work have been reduced.

Through energy forecasting, energy equipment management, energy balance forecasting, and other functional modules, scientific and reasonable statistics and analysis of energy data have been achieved, providing a scientific basis for enterprises to reduce energy consumption.

At the same time, combined with real-time monitoring, energy performance assessment, and other functional modules, the comprehensive energy consumption of enterprises will be reduced by 3% to 15%.