Intelligent system solutions

Here is the title one h1 placeholder text

- Product description

- Model specifications

- Product Features

- Other instructions

-

- Commodity name: Intelligent System Solutions - Port

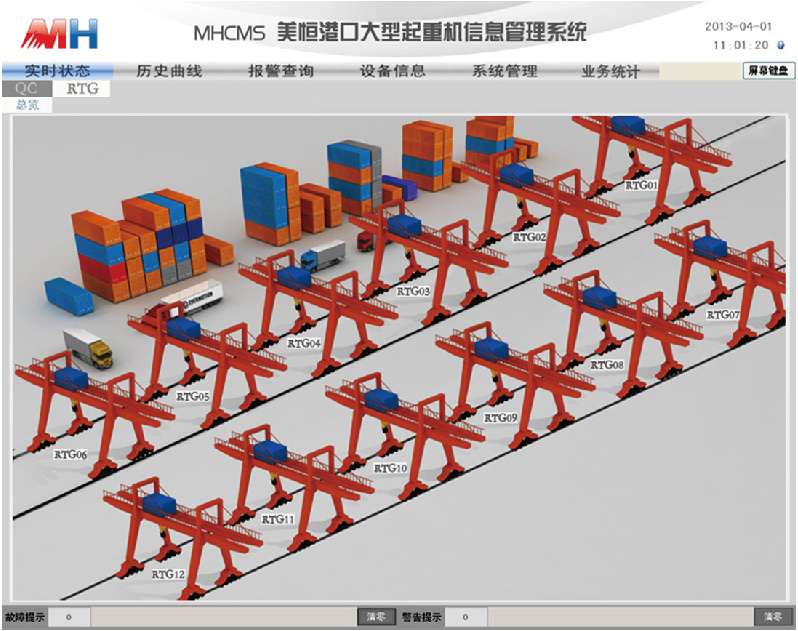

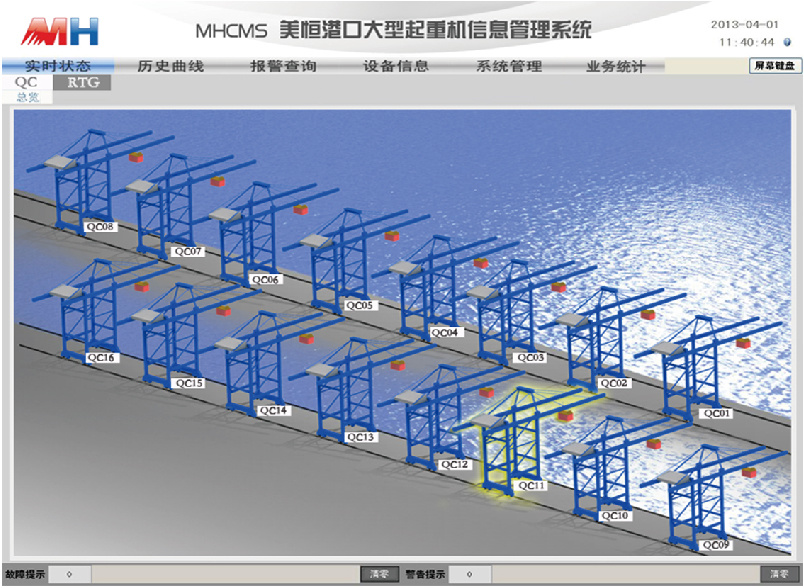

MHCIMS Port Large Crane Information Management System

1. Overview

The MHCIMS Port Large Crane Information Management System is based on Meiheng's years of industry management experience in cranes. It includes an intuitive display of the operational status of port cranes and management of equipment information, equipment fault reminders, and fault diagnosis functions. Historical operational conditions can also be observed and analyzed visually through curves. Additionally, the system provides two solutions: standalone management and networked management. The system offers the most intuitive methods, the most convenient operations, the most reliable monitoring, and the lowest costs, making it one of your best choices.

2. Network Architecture

This system is developed based on MH-SCADA and supports various network architecture methods, including: local standalone solutions, client/server solutions, and browser/server solutions. The best networking solution can be selected based on the specific application environment. The networked solution can be directly expanded from the standalone solution with low expansion costs.

The network architecture is mainly divided into three levels: MHCIMS local workstation, MHCIMS central server, and remote client (browser). All real-time data, fault information, business, maintenance information, etc., from the local workstation can be accessed and queried directly through remote terminals. Remote monitoring can also be performed directly through the IE browser.

The MH-SCADA network architecture is implemented based on a visual network programming framework, making the interface quick and intuitive, data secure and reliable, real-time, and easy to expand and maintain.

3. Network Architecture Diagram

4. Main Functions

● Distributed ManagementRemote terminals can directly overview the operational status and alarm information of all front-end cranes in the network in a distributed manner.

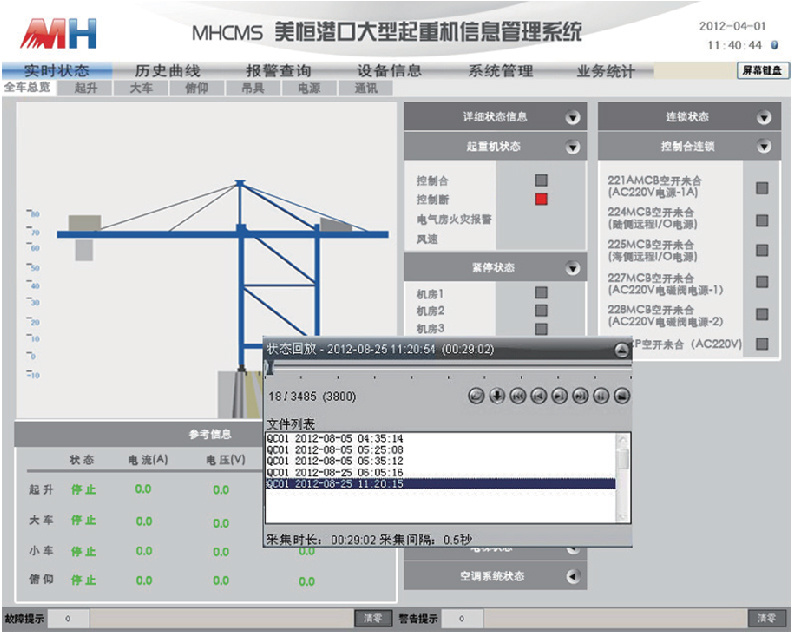

● Real-time Operational Status Monitoring

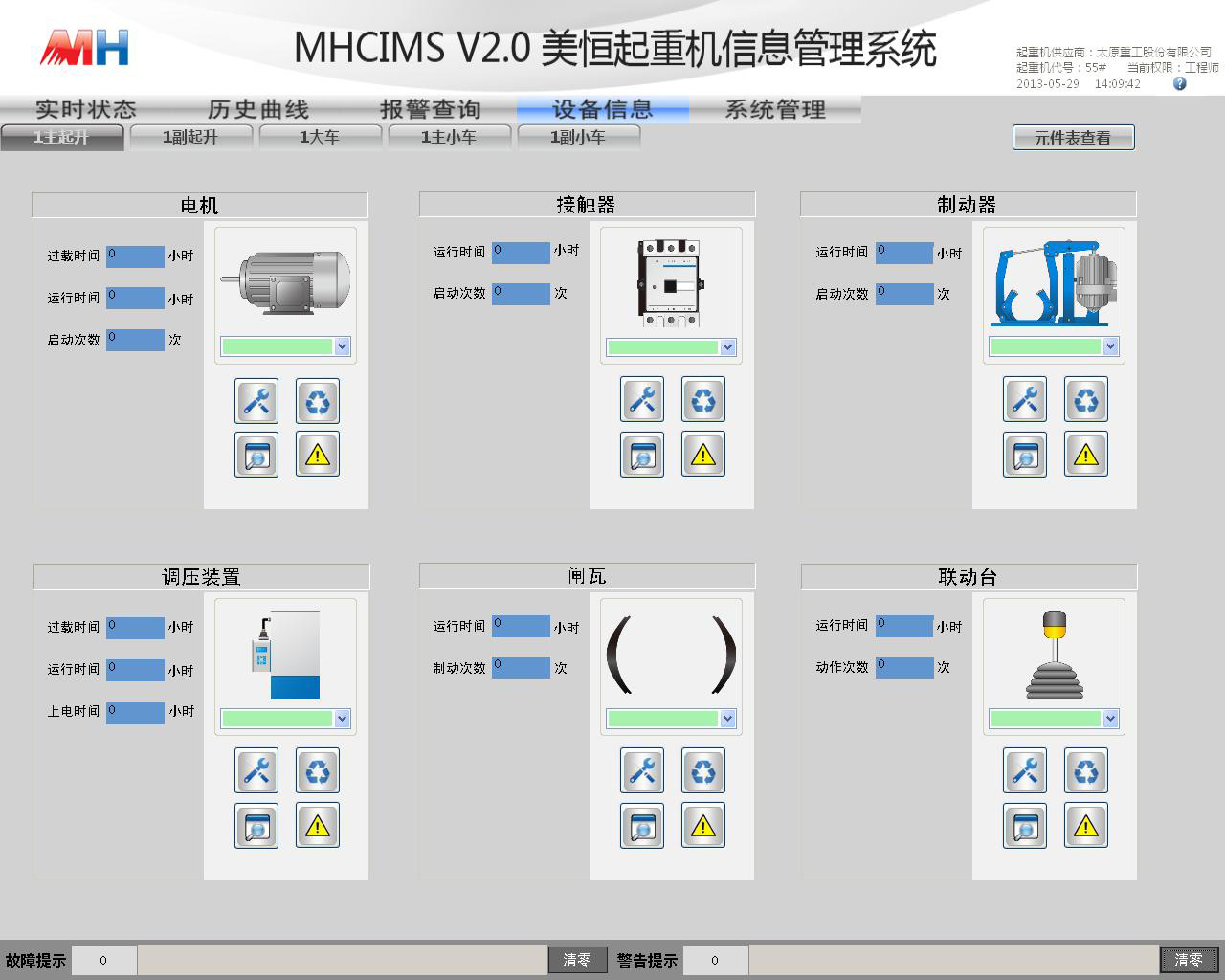

● Equipment Information Management

Supports analysis and statistics of the operating time and usage frequency of various crane mechanisms; supports pre-warning processing with customizable warning values; supports recording and management of equipment maintenance information; supports querying operational maintenance information, etc.

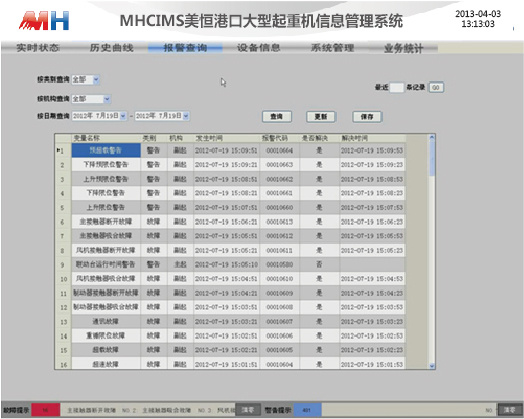

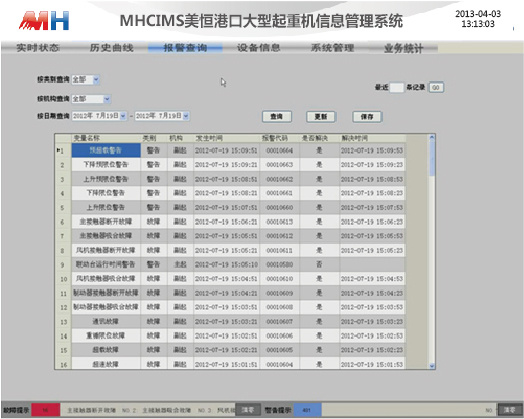

● Alarm Query and Fault Analysis

Includes historical fault queries; viewing PLC programs corresponding to faults; viewing information and documents corresponding to faults; specific fault information statistics; exporting fault information as electronic documents, and more.

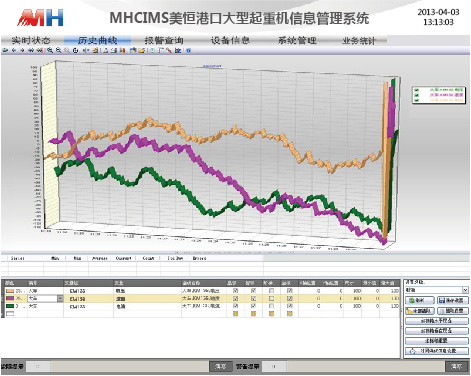

● Real-time and Historical Trend CurvesAllows selection of data curves to be observed in real-time; historical data curves can also be observed for trend analysis.

● Status PlaybackCan save various status information during equipment operation; can replay past real-time operational scenes; includes functions for saving and exporting playback files.

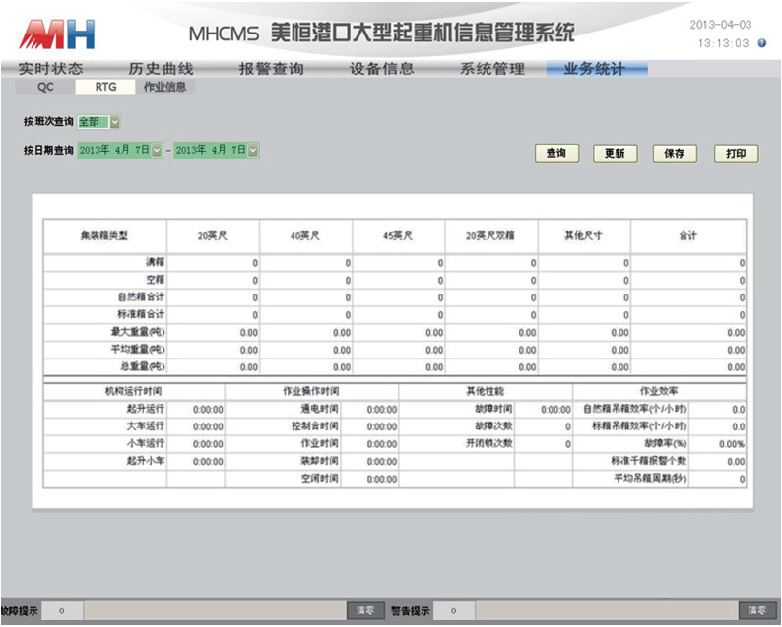

● Operation StatisticsSupports saving and querying business information, including the number of containers loaded and unloaded, dimensions, maximum weight, total weight; operating time and standby time of each mechanism within specified time; can query by date, shift, etc.; can export query information as reports and print. Can view the operation records of containers.

● File and User Permission Management

Supports multi-user login; hierarchical permission management; basic system operations; file and data management operations.

5. Expandable Functions

Port Logistics Management ModuleAs an expandable module of the Port Large Crane Information Management System, the Port Logistics Management can provide users with:

Material Management

● Material Inbound: Receives production instructions or other inbound instructions and material arrival signals, automatically records the inbound material's number, automatically generates the basic code for inbound materials, determines storage locations based on warehouse status or according to warehouse manager requirements, issues operational instructions to cranes, and records material storage location information (3D location information) based on crane feedback. Can distinguish between normal inbound and other inbound methods.

●Material Outbound: Receives production instructions or other outbound instructions and outbound vehicle arrival signals, can automatically generate outbound order numbers, can distinguish between normal outbound and other outbound methods, issues operational instructions to cranes, and records outbound information.Inventory Management: No manual management is required; when inbound and outbound occur, the system automatically generates the inventory quantity for each type of material, making queries convenient.

●Material Classification Management: When materials differ, virtual warehouses can be established to manage materials that need to be distinguished.Inventory Counting Management: Users can count the warehouse at any time, automatically generating inventory documents, making the counting work convenient and quick.

Inventory Upper Limit Alarm: The system will alarm when the inventory quantity does not meet a certain amount.Report Generation Module

●Automatic generation of inventory reports, inbound and outbound reports, and counting reports at the end of the month, quarter, and year, with user-defined report statistics.Query Function

●Material inbound queries, material outbound queries, single material queries, inventory queries, etc. (user-defined).

●Queries are based on certain conditions: material code, material number, inbound or outbound date, etc.

Material Tracking Query Function

●Material tracking queries are mainly completed by the ERP system, and this software will exchange data with the ERP system to assist in material tracking queries.

Can manage and query the history of inbound materials.Warehouse Area Image Function

Displays and manages all warehouse area images, while updating warehouse area images based on crane processing data.The Port Logistics Management Module can also serve as an independent logistics management system for users to manage inbound and outbound materials according to the actual situation and needs of the user’s site, improving material management levels. It also supports linking the system with the user's ERP system for data exchange, enhancing port management capabilities.

Meiheng Company, based on MH-SCADA technology, in addition to the large crane information management system for ports, can also provide users with a port cluster equipment management system.