Intelligent system solutions

Here is the title one h1 placeholder text

- Product description

- Model specifications

- Product Features

- Other instructions

-

- Commodity name: Intelligent System Solutions - Shipbuilding

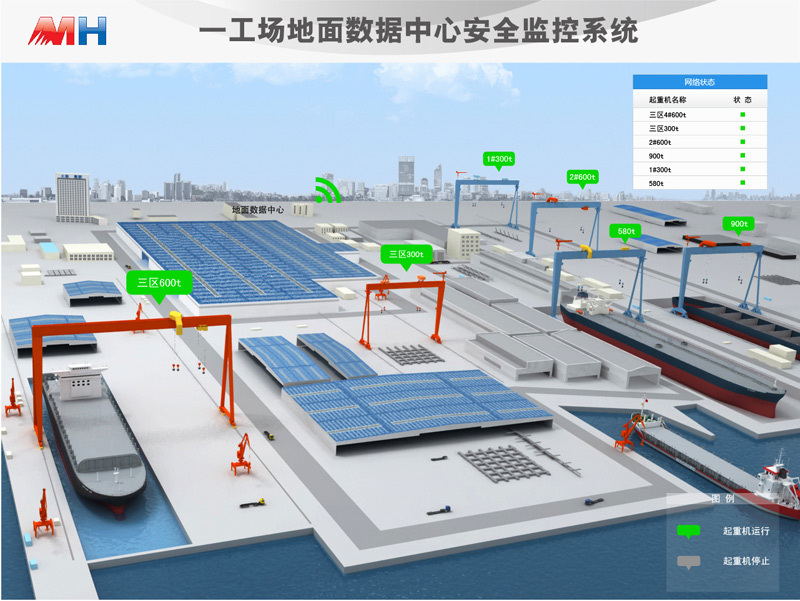

Shipyard Gantry Crane Safety Monitoring Data Center

1. Case Background

The gantry crane is an important lifting equipment used in shipyards and docks for the assembly of large structural sections and the installation of electromechanical equipment during ship repair and construction. Due to its large lifting capacity and high precision requirements, its safety and work efficiency have always been a focus of concern for shipyards. The state attaches great importance to the safety of cranes and has issued the national standard GB/T 28264-2012.It clearly states that cranes must have supporting safety monitoring system software. Based on their equipment management needs and national standards, shipyard owners have proposed the following requirements for the safety monitoring system:

lThe system must have safety monitoring functions to achieve real-time monitoring and recording of gantry crane data, ensuring equipment safety and improving production efficiency;

lThe system must have alarm statistics functions to effectively predict potential risks, reduce alarm rates, and ensure long-term stable operation of the equipment;

lThe system must have inspection management functions, making equipment maintenance management more scientific, enabling departments to work together in an orderly manner, and improving maintenance efficiency;

lThe system must have expert diagnosis functions to effectively assist shipyard owners in solving difficult problems and quickly eliminating faults.

2. Case Analysis

According to the needs of the shipyard industry, Meiheng Company has developed a domestic leading level gantry crane safety monitoring system based on the MH-SCADA.Configuration development software as the core platform.

lSystem Composition

The gantry crane safety monitoring system consists of a crane maintenance station, wireless network, and ground data center.Components.

The crane maintenance station is installed in the driver's cabin. It connects to the gantry crane control system through a field bus to collect, record, and analyze data from inverters, PLCs, sensors, videos, and other equipment in real-time.The wireless network uses Meiheng's MHRD series industrial radio stations to meet the shipyard's long-distance transmission requirements.

The ground data center obtains data from the crane maintenance station through the wireless network, displaying the operating status of each gantry crane in real-time. The ground data center interacts with the shipyard's MES through a wired network to provide data support for factory-level management, thereby improving production efficiency.System Features

Real-time monitoring and recording,acting as a black box for key equipment data of the gantry crane, providing important evidence for future fault diagnosis and accident identification.

lOverview monitoring of the operating status of all gantry cranes in the shipyard can promptly identify equipment issues, locate problems, shorten fault diagnosis time, and ensure equipment safety.

Management and analysis of alarm data from the gantry crane help maintenance personnel summarize common fault types, causes, trends, and other key information, making system maintenance targeted.The electronicization of inspection work planning, execution, review, recording, and spare parts management for the gantry crane helps maintenance personnel efficiently execute inspection work, refine inventory management, and assist managers in evaluating the quality of inspection work and performance management.

The built-in fault expert system helps equipment management personnel quickly find fault causes and provides fault handling suggestions to shorten fault diagnosis time and ensure equipment safety. It also supports user self-learning functions, helping equipment management personnel effectively accumulate and pass on work experience.

3. User Benefits

The gantry crane safety monitoring system helps users improve the safety management level of equipment, reduce equipment failure rates, and enhance the stability of equipment operation, ultimately ensuring the production efficiency of shipbuilding operations. At the same time, this system also helps customers improve spare parts management, optimize spare parts inventory, enhance the quality of inspection work, ultimately reducing production costs and improving equipment maintenance levels.

Product Link:

Crane Division

MHCIMSMHRD Industrial Radio

起重机事业部

MHCIMS

MH-SCADA

MHRD工业电台