Intelligent system solutions

Here is the title one h1 placeholder text

- Product description

- Model specifications

- Product Features

- Other instructions

-

- Commodity name: MH-SCADA configuration system development software

- Commodity ID: 1323586988929601536

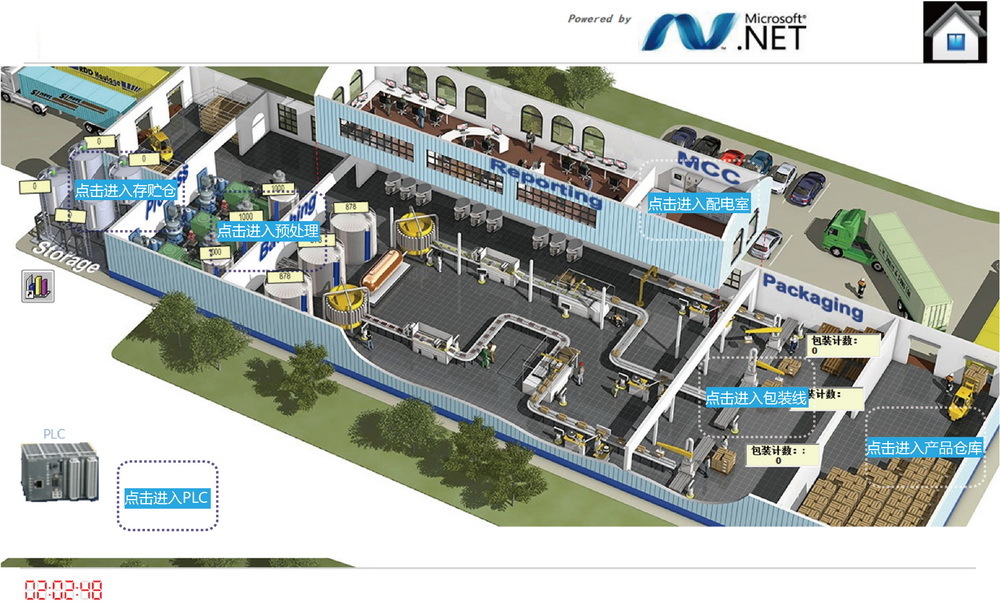

MH-SCADA is an object-oriented, highly open, and efficient visualization configuration software for controlling automation processes. As a modern software expert system, it can be used in applications such as office automation, community management, mining, water treatment, cement, steel, and more. It also serves as a platform for IT and business integration, featuring strong flexibility, reliability, scalability, and efficiency.

From a technical perspective, MH SCADA is a configuration software developed based on Microsoft .NET technology, with strong data compatibility. It can securely and reliably access various data sources (OPC, SCADA, MES, ERP, WEB SERVICES, etc.) through local area networks or the Internet, while also offering powerful graphical capabilities (vector graphics), a distributed and modular design environment (allowing multiple users to develop a project simultaneously), flexible development languages (C#, VB.NET), and personalized development modules (supporting custom control development).

Product Features

● Inherited and enhanced the characteristics of traditional configuration software, including integrated device drivers, visual development environments, and easy action settings.

● Further designed graphical script programming tools that open up programming interfaces for high-level languages (such as C#, VB.NET, etc.).

● Added a large number of user-customizable elements such as templates, wizards, controls, dynamic link libraries, and data sources.

● Supports online design by multiple users and interface multilingual switching.

● As a comprehensive configuration development platform, it has been successfully applied in Europe, America, Southern Africa, China, and other countries and regions in Asia.

Additionally, Meiheng Company also provides customization and cooperation services for information management systems and resource management systems to meet various personalized needs of users.Product Overview

MH-SCADA is based on MH Company's practical experience of providing thousands of sets of SCADA software and HMI software to users in over 20 countries for more than 10 years, combined with the current trends in cloud computing and Internet of Things technology, making it a world-class configuration system development platform.

MH-SCADA is a comprehensive software development toolkit that meets a wide range of industrial software application requirements while retaining the ease of use of traditional configuration software.

Product Architecture

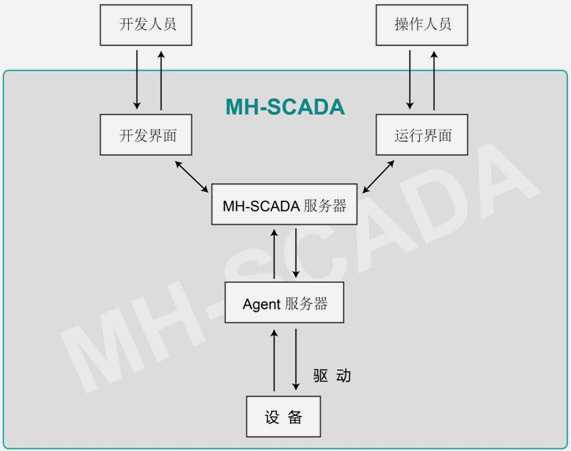

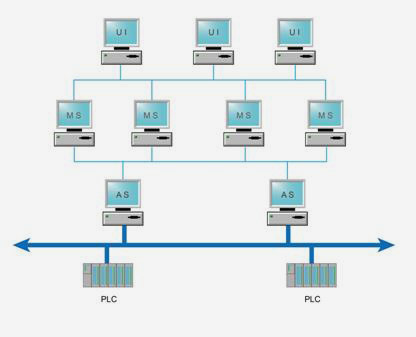

MH-SCADA features a true distributed architecture, consisting mainly of four components: Agent Server (AS), MH-SCADA Server (MS), Development Interface, and Runtime Interface (UI).

Agent Server

The Agent Server is responsible for managing Agents (similar to "variables" in traditional configuration software) and collecting and transmitting data from devices through drivers.

The Agent Server is developed using Microsoft's Visual Studio C++ language to ensure the efficiency and stability of data collection and transmission.

MH-SCADA Server

The MH-SCADA Server is responsible for storing graphical forms, preset files, and other objects in project files, and serves as a bridge for data interaction between the Agent Server and the Development and Runtime Interfaces.

The MH-SCADA Server is developed using Microsoft's Visual Studio C# language to ensure the stability and scalability of network functions.Development Interface

The Development Interface is responsible for the design and development of MH-SCADA projects, allowing users to design graphical forms, set user permissions, configure preset files, preview, and debug screens.

Runtime Interface

The Runtime Interface is responsible for running projects designed by the Development Interface, enabling human-machine interaction.

Development Environment

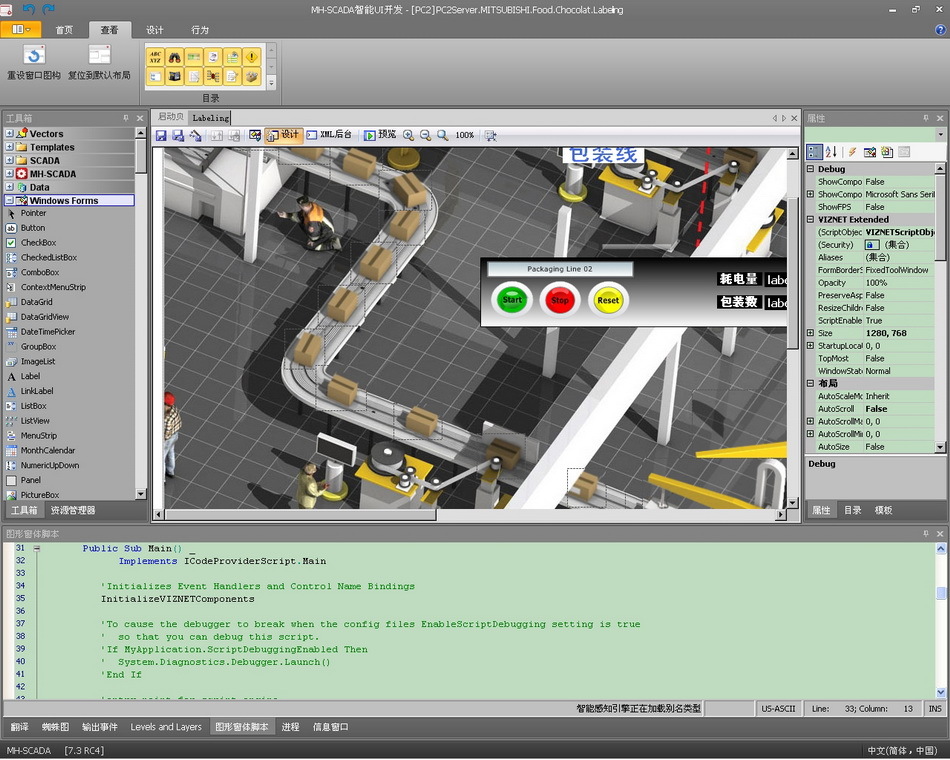

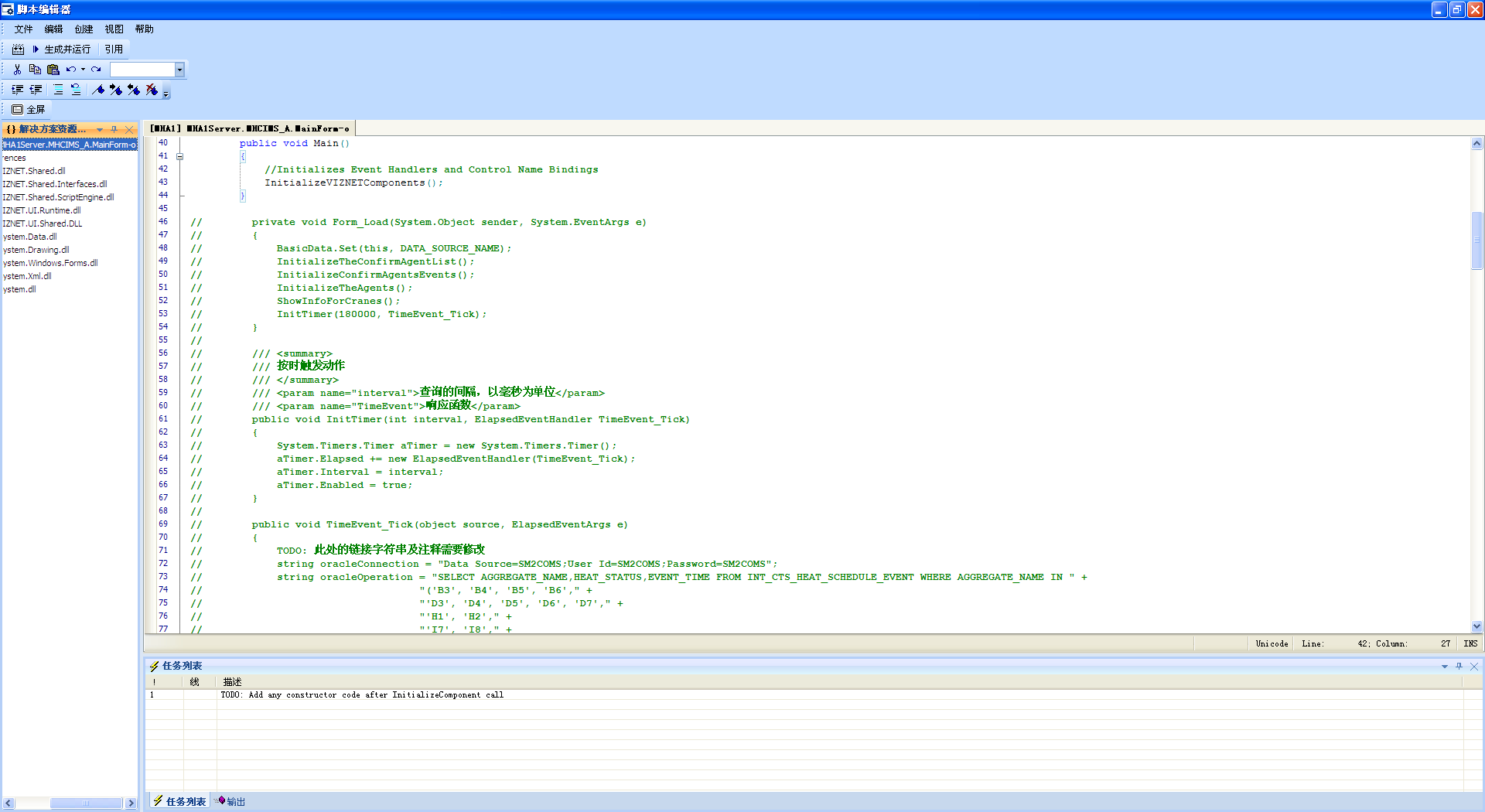

The MH-SCADA Development Interface features a development environment similar to Microsoft Visual Studio and supports mouse drag-and-drop actions, allowing users to easily create graphical forms, set control properties, add/delete data, edit scripts, and more within the same interface, without the need to frequently switch between different windows as in traditional configuration software.

Vector Graphics Technology

MH-SCADA supports the drawing of vector graphics, which are easier to draw and modify compared to traditional bitmap graphics. It supports seamless scaling of graphics without loss of clarity and resolution, allowing users to design beautiful graphical interfaces more easily.

Online Configuration Technology

Traditional configuration software uses "offline configuration technology," meaning that after modifying variables, control properties, or graphical interfaces in the development environment, the runtime interface needs to be restarted to compile the new configuration, resulting in low work efficiency. In contrast, MH-SCADA uses "online configuration technology," where new configurations do not require compilation. After clicking the "save" button in the development environment, the relevant configurations will be automatically updated without restarting the runtime interface, thus improving user work efficiency.

Click Once Technology

MH-SCADA's WEB publishing uses Microsoft's Click Once technology, allowing B/S architecture web publishing to run static screens and objects locally like C/S architecture, exchanging dynamic data only through the network, while fully retaining the advantages of a thin client in B/S architecture. Operations such as upgrades, maintenance, modifications, and expansions can be completed only on the server side, allowing the client to achieve a one-time download through the browser for long-term rapid operation.

Distributed Development Technology

Due to the distributed architecture of MH-SCADA, which includes the Agent Server, MH-SCADA Server, Development Interface, and Runtime Interface, MH-SCADA supports independent development of different component parts of the same project as well as simultaneous development by multiple developers on the same component.

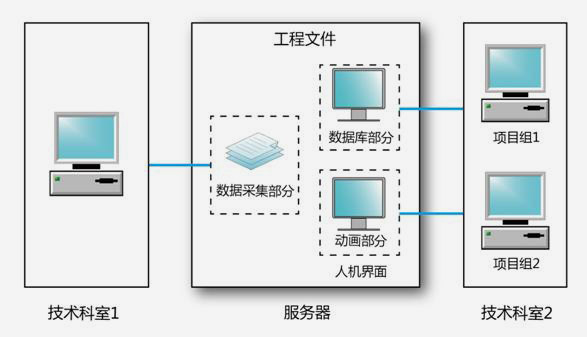

For example, the overall project files are stored on the server, and Technical Department 1 connects to the server via the network to remotely develop the data collection part of the project. Technical Department 2 connects to the server via the network to remotely develop the human-machine interface part, with the database and alarm management being handled by Project Group 1 and Project Group 2 of Technical Department 2, respectively. A schematic diagram of distributed development is shown below.

Therefore, in large systems, the distributed development technology of MH-SCADA offers significant flexibility and efficiency compared to the serial development approach of traditional configuration software.

VB.NET and C# Scripts

MH-SCADA supports C# and VB.NET programming languages, allowing seamless integration with form programming scripts in Visual Studio. This means that MH-SCADA can achieve all the functionalities of form programming in Visual Studio, enabling users to freely manipulate data, manage third-party data, control graphical elements, and more, thus providing a powerful technical platform for developing high-level management systems.

Spider Chart Functionality

Compared to traditional configuration software that uses script programming to achieve logical functions, MH-SCADA innovatively introduces a visual programming language similar to function blocks in PLC programming—Spider Diagram, which can often replace scripts to complete complex logical functions.

Spider Diagram is more suitable for engineers who are not familiar with script programming, allowing them to program by editing visual logical function blocks, thus its advantages over traditional configuration software's script programming are evident.

OEE Function

The unique OEE Agent of MH-SCADA allows for convenient OEE calculations through simple parameter settings and data recording, eliminating the need for complex professional development, making high-end production management functions easy to design.

Note:

OEE, or Overall Equipment Effectiveness, is a tool used to measure the ratio between actual equipment capacity and theoretical capacity. It is a simple, continuous, and efficient production management tool widely used in MES (Manufacturing Execution System).

The unique Alarm Management Agent of MH-SCADA is an integrated alarm management dedicated Agent, which allows for simple recording, management, statistics, analysis, and automatic generation of alarms without complex database development and script editing.Clustering Function

Compared to the hot backup function limited to data collection in traditional configuration software, MH-SCADA supports comprehensive clustering functions.

The Agent server can implement a master-slave mode for hot backup of data collection functions to ensure the real-time and completeness of data collection;.

The MH-SCADA server has load balancing capabilities, allowing for dynamic load distribution among multiple MH-SCADA servers, reducing the burden on single-machine systems, ensuring the stability of real-time operation of engineering files, which is particularly advantageous in large systems.

Due to the distributed architecture of MH-SCADA, multiple development interfaces and runtime interfaces can run simultaneously, all connected to the same MH-SCADA server.

In summary, all components of MH-SCADA have clustering functions. Combined with the distributed architecture of MH-SCADA, it achieves true clustering functionality, and the overall operational stability of the system is unmatched by traditional configuration software.

Openness

Unlike the closed nature of traditional configuration software, MH-SCADA embodies the spirit of openness. In addition to supporting standard open interfaces, it also provides many development toolkits, supporting users in custom development of drivers, data sources, spider diagrams, libraries, and ActiveX controls. This greatly meets the personalized design needs of customers.

Applicable Fields of the Product

MH-SCADA is suitable for process control, management monitoring, fault diagnosis, and production execution systems in various industries and fields such as petrochemicals, automotive, metallurgy, pharmaceuticals, construction, mining, environmental protection, electricity, transportation, intelligent buildings, warehousing, logistics, and water conservancy.

For more detailed information, please refer to the main website of MH-SCADA:www.mh-scada.com. -

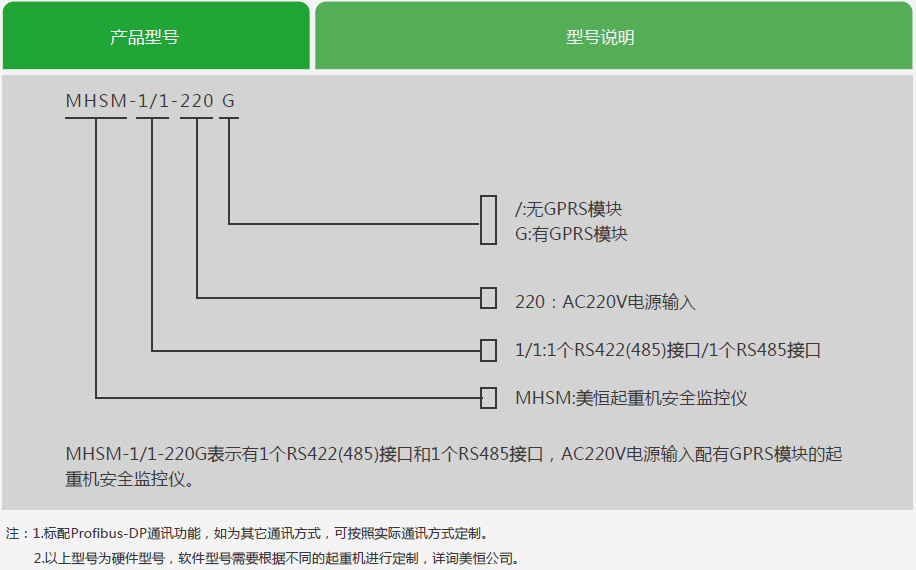

Model Description

-

Product Features

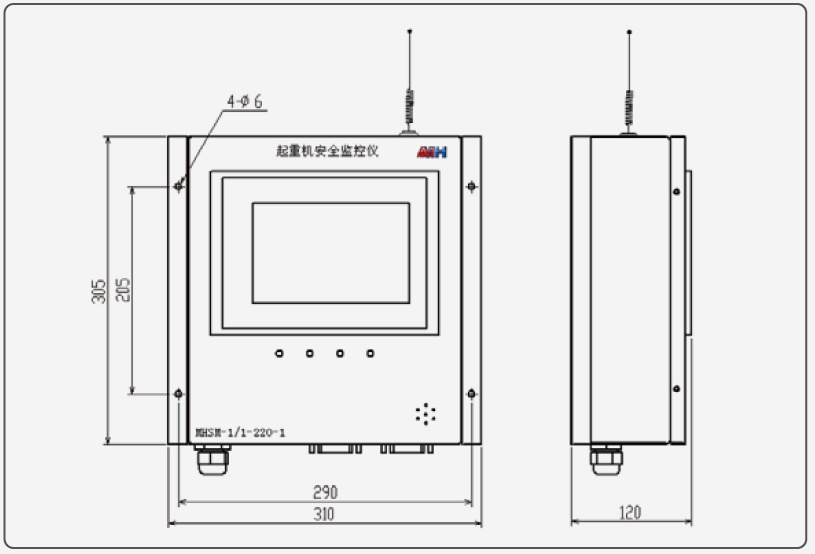

●Meets the requirements of the national standard GB/T 28264-2012 "Safety Monitoring and Management System for Lifting Machinery."

●Widely used in various types of cranes such as bridge, gantry, portal, tower, cable, mast, and mobile cranes as specified in GB/T 20776-2006.

●Comprehensive functionality, capable of monitoring conventional operational parameters such as lifting weight, lifting height, and working time.

●Data can be wirelessly transmitted to a remote monitoring platform via GPRS, facilitating quantitative management by quality supervision departments.

●Provides prompts and alarms for the normal operation, full load, and overload states of the crane.

●Real-time recording and storage of the crane's safe working conditions, effectively preventing and stopping accidents.

●Uses PIC32 microcontroller for fast data processing.

●Has powerful communication capabilities, able to communicate with various hardware devices such as PLCs.

●User-friendly interface that is more intuitive and easy to operate.

●Diverse system permission management ensures the reliability of operations. -

Technical Parameters

Specifications and Dimensions