Intelligent system solutions

Here is the title one h1 placeholder text

- Product description

- Model specifications

- Product Features

- Other instructions

-

- Commodity name: Automated System Solutions for Lifting and Transport Machinery

Intelligent system solutions for lifting and transportation machinery

1. Background of the solution

The intelligent system solution for lifting and transportation machinery is an information solution developed by Meiheng Company specifically for the safe operation monitoring and comprehensive information management of lifting and transportation machinery. It provides users with an overall intelligent solution based on relevant standards, tailored to the actual situation of the users, and can also create personalized information management solutions for cranes.

The intelligent solution for lifting and transportation machinery includes functions such as intelligent control, drive integration, safety monitoring, information management, and comprehensive big data analysis, providing a "one-stop" integration and service for the intelligent solution of cranes. It improves the safety performance, control accuracy, and information level of lifting and transportation machinery, saving costs for enterprises using lifting and transportation machinery, enhancing management levels, and improving work efficiency.

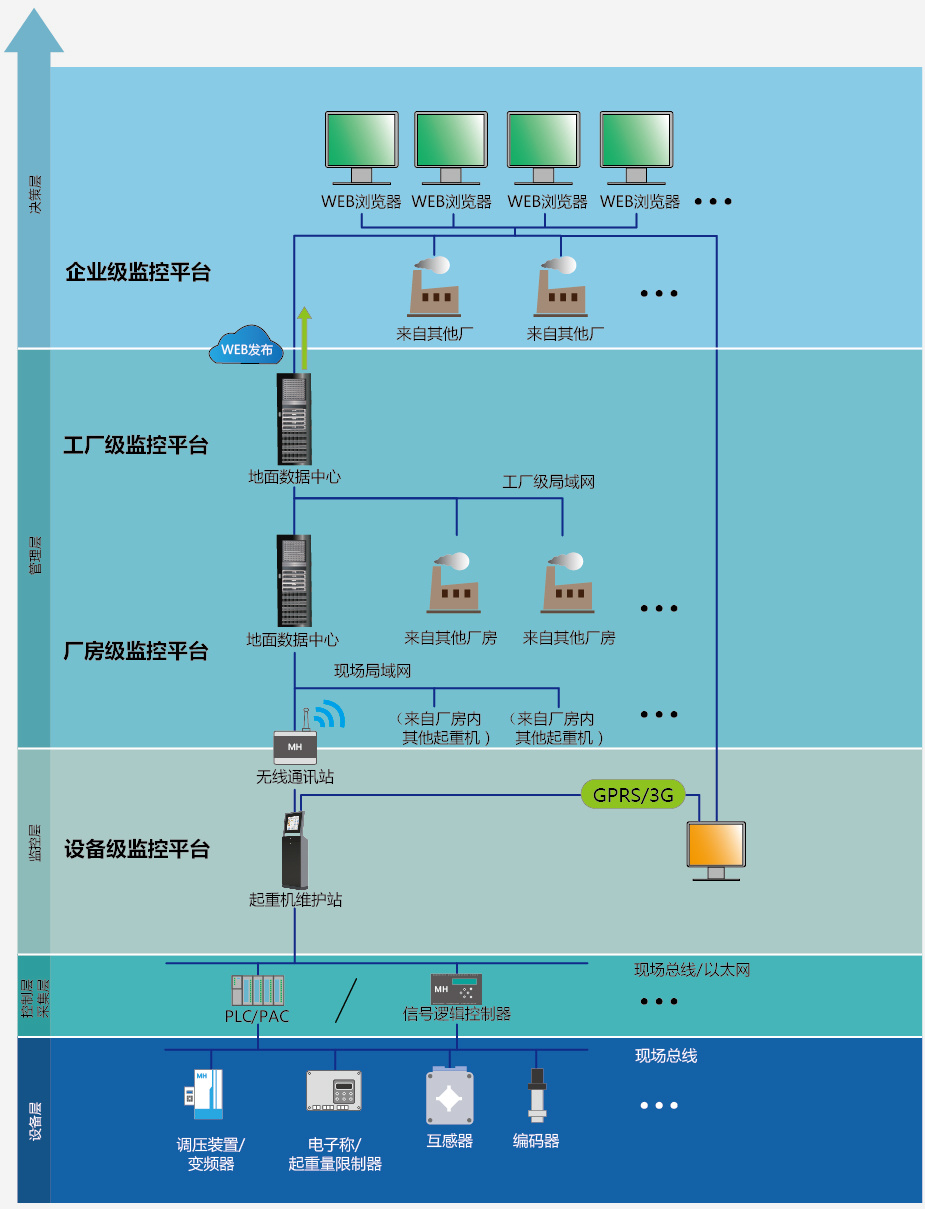

2. Solution architecture

3. Solution features

l Full bus control of cranes and Ethernet communication, achieving savings in wiring, easy expansion, and facilitating intelligent control of cranes.

l Integrating motor drive, information perception, logic control, and computer interface communication into a comprehensive intelligent system for management.

l Comprehensive collection and recording of safety parameters and operational parameters of cranes, making it easy to obtain data and conduct analysis.

l Integration of control layer, monitoring layer, factory level, and enterprise level into a comprehensive intelligent system, providing an integrated platform.

l Supports operation and maintenance management of lifting and transportation machinery, preventive maintenance of equipment, and management of equipment efficiency and production effectiveness.

l High-speed data acquisition at 100ms, massive data storage and analysis, and historical data backtracking of the same level.

l Overall communication adopts internationally recognized communication protocols to support compatibility with other systems.

4. Function implementation

l Integration of intelligent control

Through a full bus control system architecture, combined with drive devices equipped with detection and communication functions, and supplemented by sensors collecting relevant crane data, real-time information is aggregated into the PLC controller, achieving an integrated control solution for cranes that includes sensing, measurement, control, and monitoring..

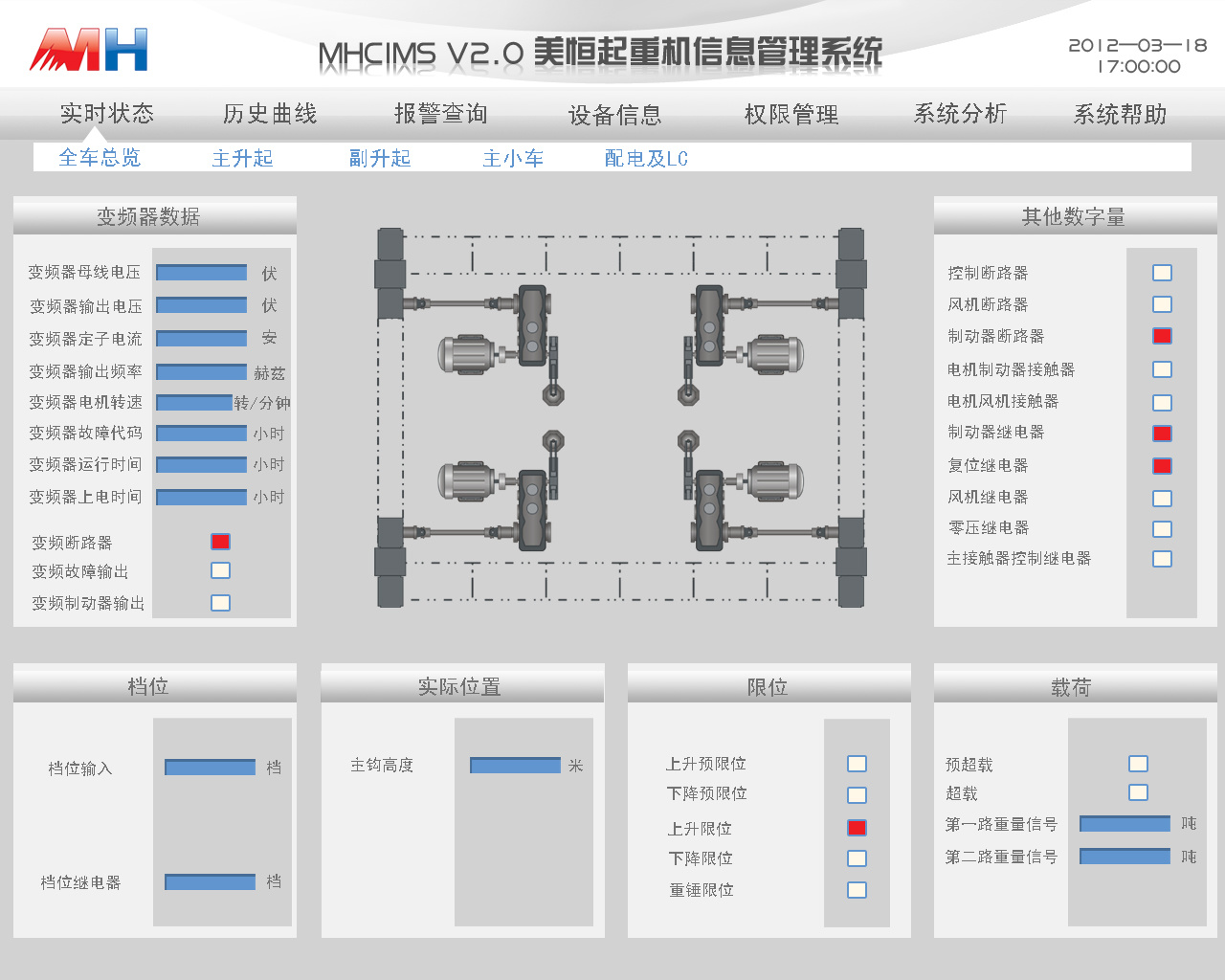

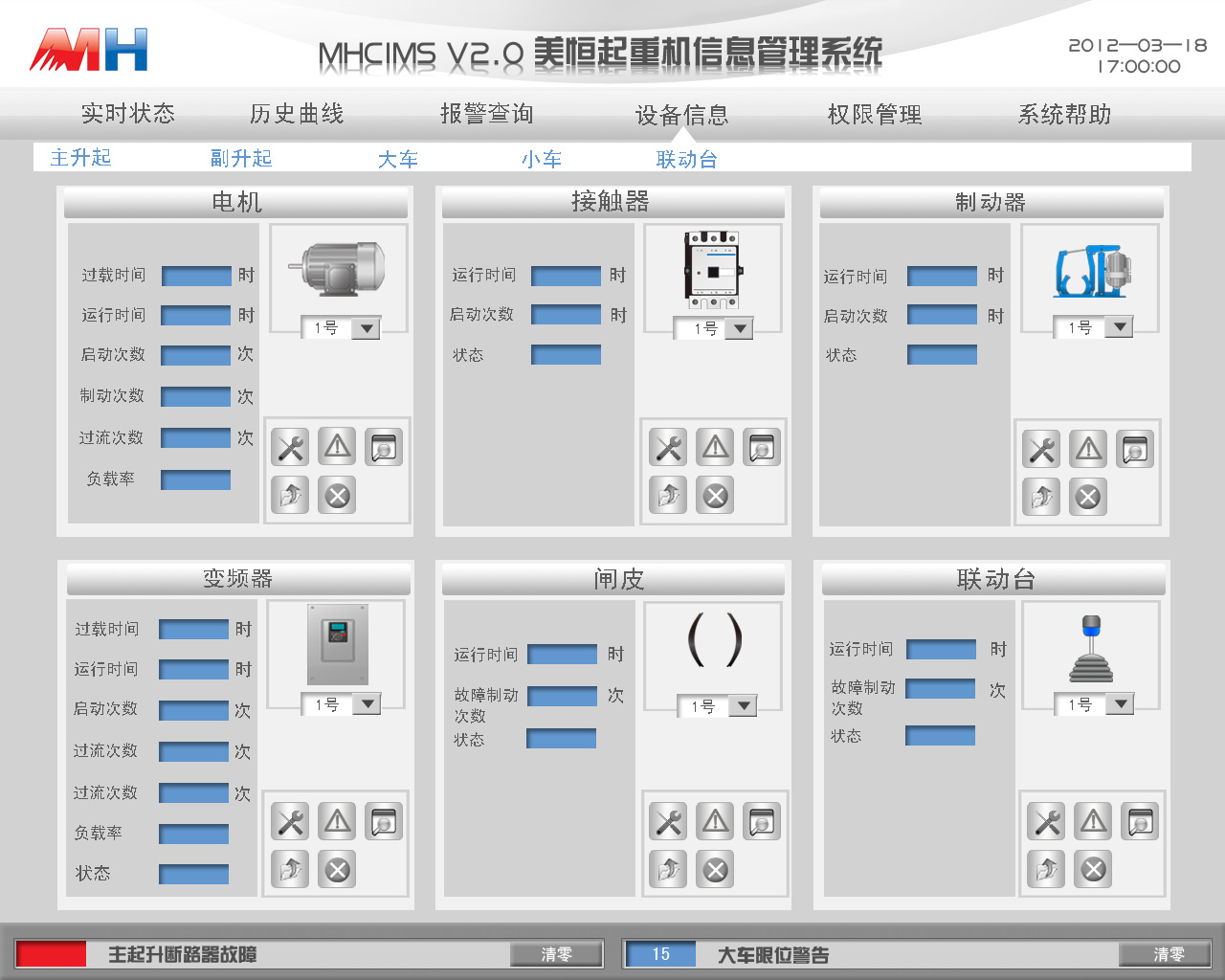

l Real-time monitoring of cranes

By comprehensively obtaining real-time information on crane operations, real-time monitoring of safety parameters and electrical parameters of cranes is achieved, with all monitoring parameters meeting the relevant requirements of national standard GB/T 28264-2012. Safety parameters are visually displayed through vector graphics.

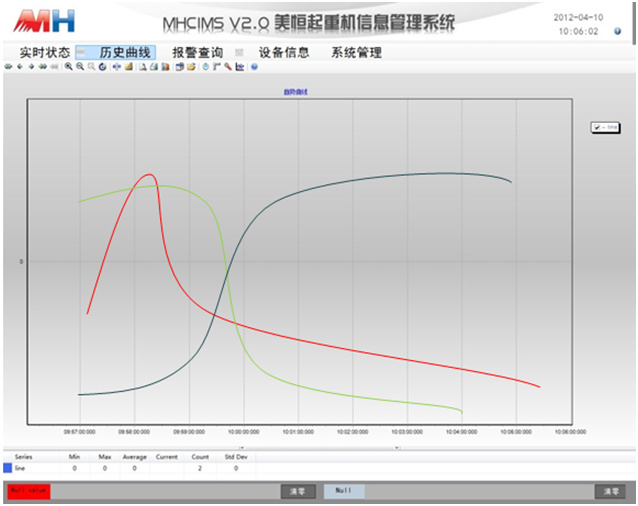

Historical trend curves

At 100msintervals, quickly acquire and record crane operation data, supporting historical record retrieval with the same precision. Historical data results are displayed in curve form, facilitating intuitive judgment of crane status at a specific time. Historical trends are grouped for display according to crane control processes, while also supporting user-defined curve additions and queries.

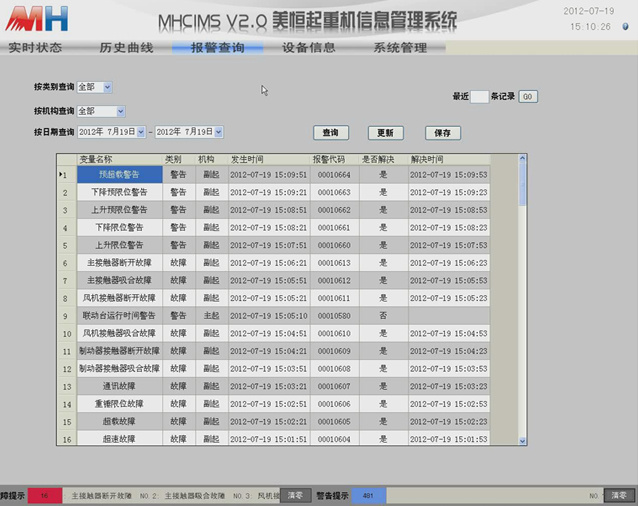

l Alarm management and query

Records alarm information generated during crane operation, allowing for complex condition queries based on time, alarm type, operational mechanism, etc., facilitating quick fault location and avoiding difficulties in finding due to the simultaneous display of a large amount of alarm history.

l Equipment operation information

Statistics on equipment action counts, power-on time, overload time, and other lifespan indicators based on actual equipment operation conditions, with the ability to set warning values. When the actual cumulative operation of the equipment reaches the warning value, the system will issue a preventive maintenance warning, prompting maintenance personnel to conduct preventive inspections and repairs in advance.

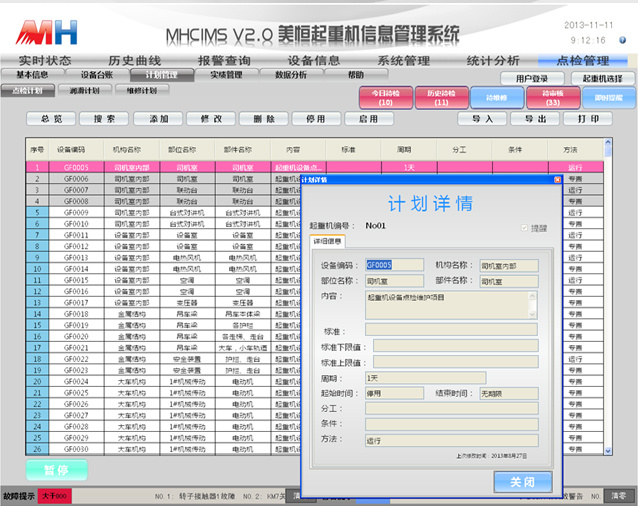

l Inspection management system

The inspection management system is an information management module designed by Meiheng Company specifically for the maintenance and repair of lifting and transportation machinery. It supports online viewing of crane data, scheduling of inspection plans, reminders for inspection work, submission and review processes for inspection results, statistical analysis of inspection work effectiveness, and online fault assistance systems, among other functions. It helps users of lifting and transportation machinery improve equipment management levels, strengthen inspection and patrol work, reduce the workload of operators, and enhance equipment management efficiency.

l Health management

The health management system originates from the preventive analysis needs for the safe operation of cranes. Its key point is the continuous monitoring of key parameters of cranes, based on big data processing and analysis concepts, extracting performance degradation indicators and their change patterns from accumulated massive data, achieving preventive analysis of operational hazards of cranes, eliminating crane faults before they occur, reducing the unexpected failure rate of cranes, minimizing fault losses, and improving crane safety performance, ultimately reducing economic losses for enterprises.

l Efficiency/Energy efficiency management

Utilizing big data processing concepts and algorithms, analyzing data related to crane usage efficiency from the daily operation data of lifting and transportation machinery, and visually presenting it in chart form. By focusing on equipment energy efficiency, the goal is to improve the application efficiency of enterprise equipment, helping users fully utilize crane equipment resources, reasonably arrange production plans, balance loads among cranes, and achieve balanced, scientific, and efficient operations, ultimately realizing true savings for enterprises.

l Mechanical diagnosis

For lifting and transportation machinery, obtaining electrical parameters is relatively simple and easy to achieve, but the performance and operational status of key mechanical components are also crucial. In the past, such data was often difficult to obtain directly online through information systems and often relied on manual experience for judgment.

Meiheng Company has designed online monitoring for gear reducers for cranes, helping users obtain the wear conditions of key mechanical components of cranes, achieving integrated management of electromechanical information and expert-level system diagnosis.

5. User benefits

The intelligent system solution for lifting and transportation machinery enables top-down integrated management and intelligent operation of cranes, helping crane users achieve comprehensive intelligent operation and maintenance from equipment control to information management, and from equipment safety to production efficiency, improving equipment utilization efficiency, reducing safety failure risks, and helping enterprises achieve fundamental cost savings.