Intelligent system solutions

Here is the title one h1 placeholder text

- Product description

- Model specifications

- Product Features

- Other instructions

-

- Commodity name: Case Study of Information Management System for Casting Cranes

Casting Crane Information Management System Case

1. Case BackgroundThe operation of casting cranes is a high-intensity, high-vibration mechanical process. This case is applied in a large steel enterprise, where the site conditions impose high requirements for the electrical equipment's protection against high temperature, high humidity, vibration, dust, and electromagnetic interference. The system needs to monitor 6 units of 140T casting cranes, of which 4 are continuous casting cranes (with a span of 500 meters) and 2 are converter cranes (with a span of 600 meters). To ensure the safe transfer of high-temperature molten steel and 24-hour uninterrupted production, the steel enterprise introduced the MHCIMS system to enhance the safe operation of the cranes and reduce maintenance time and spare parts costs.

2. Case Analysis

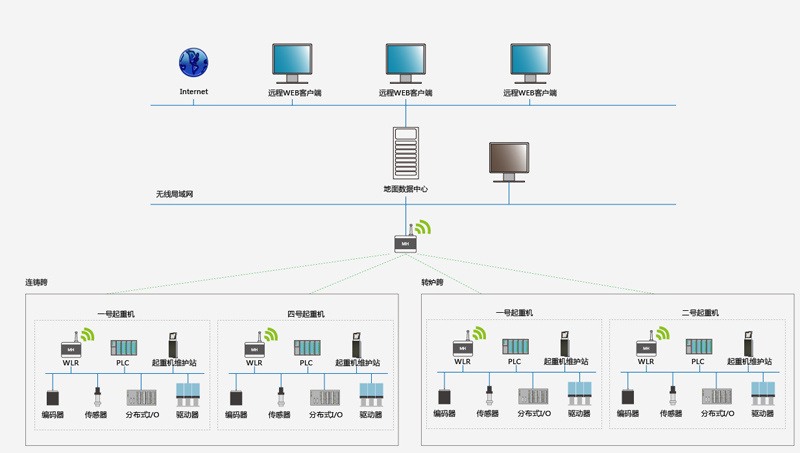

The system mainly consists of three parts: the crane maintenance station, wireless devices, and the ground data center. The crane maintenance station is installed in the electrical room of the crane, used for communication with the PLC, collecting on-site data, and monitoring the crane. Wireless devices are installed on the crane's end beam and walkway, responsible for transmitting data from the crane maintenance station to the ground data center via wireless network. The ground data center is installed in the monitoring center office, collecting all data from the crane maintenance stations, centrally managing the 6 cranes, and communicating with the enterprise MES system to achieve scheduling management of the 6 cranes.3. System Block Diagram

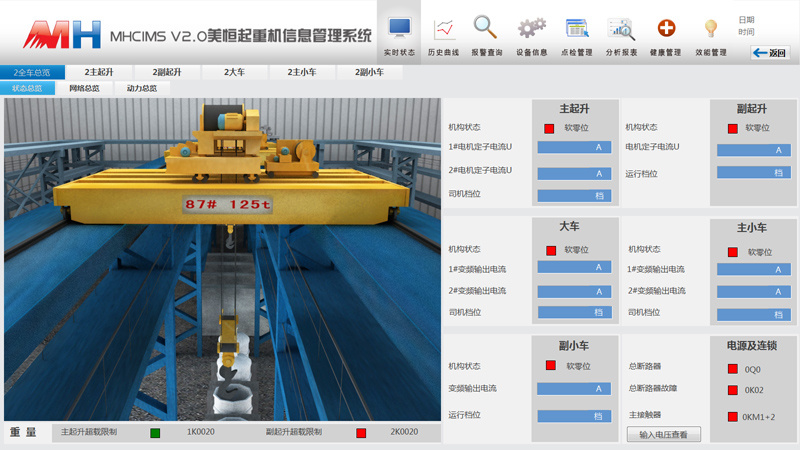

4. System Functions

To meet the demands of the site environment, the crane maintenance station adopts a compact structural design. An industrial computer with an embedded controller is used as the data processing unit in the crane maintenance station, and a lightweight monitor is used for the human-machine interface. All of the above equipment has undergone professional anti-vibration design, protection level, and high-temperature treatment. The wireless devices are equipped with multi-input-output antennas, have strong anti-interference capabilities, and ensure smooth and stable wireless transmission.

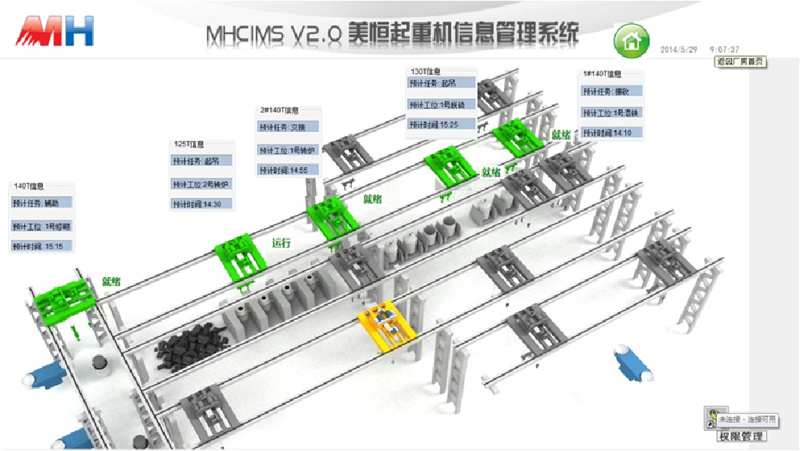

To achieve crane scheduling management, the MHCIMS system communicates with the enterprise MES system, regularly reads tasks sent by the MES system, and sends information to each crane. All cranes execute lifting tasks in an orderly manner according to the assigned task plan. At the same time, it statistics the workload and efficiency of the cranes, analyzes the working patterns of the cranes, and optimizes crane scheduling.

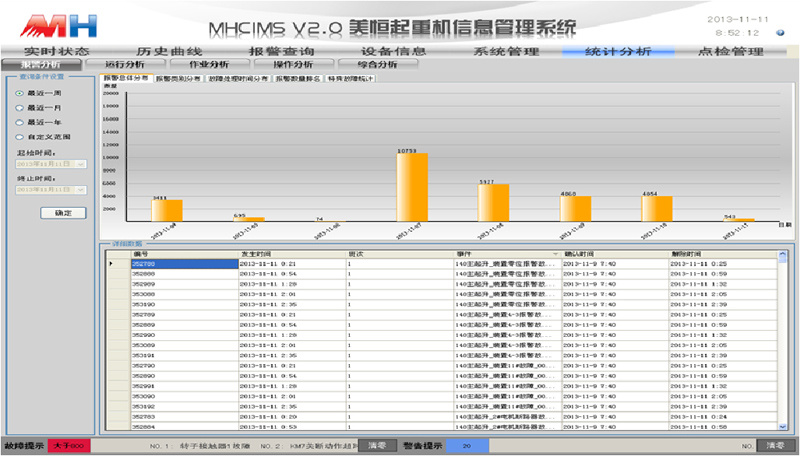

Comprehensive alarm management, complete document management (such as drawings and technical materials), and an open interface function for direct access to PLC programs provide strong information support for troubleshooting and problem handling; calculating and statistics the lifespan of key electrical components of equipment, such as motors, inverters, contactors, brakes, and brake linings, provide data basis for preventive maintenance of equipment, improve equipment work efficiency, and also provide reference data for more reasonable and effective spare parts procurement, reducing spare parts inventory.

5. User Benefits

Since the system was put into use in September 2012, it has fully met the centralized monitoring and management needs of the 6 cranes, ensuring that the cranes always operate in a safe, efficient, and reliable state.

In the future, this system will also expand the inspection management function, build an integrated data platform for monitoring, management, and analysis, comprehensively optimize crane operation and maintenance, improve safety, production efficiency, and reduce maintenance, spare parts, and personnel costs.

Related Links: MHCIMS