Intelligent system solutions

Here is the title one h1 placeholder text

- Product description

- Model specifications

- Product Features

- Other instructions

-

- Commodity name: Intelligent Remote Service System Solution

1. Background of the Plan

The remote monitoring system utilizes the existing computer network of the enterprise to monitor and manage the operational data of on-site equipment, allowing equipment manufacturers, on-site maintenance personnel, and others to timely and accurately understand the operational status of the equipment, identify problems during operation, and perform remote maintenance and technical support promptly. Through remote monitoring, the operational status of the equipment can be grasped in real-time, dynamic data can be accurately captured, and comprehensive monitoring of equipment operation can be achieved, providing users with effective maintenance suggestions, improving the efficiency of problem detection, and assisting in future process improvements, while significantly reducing maintenance costs.

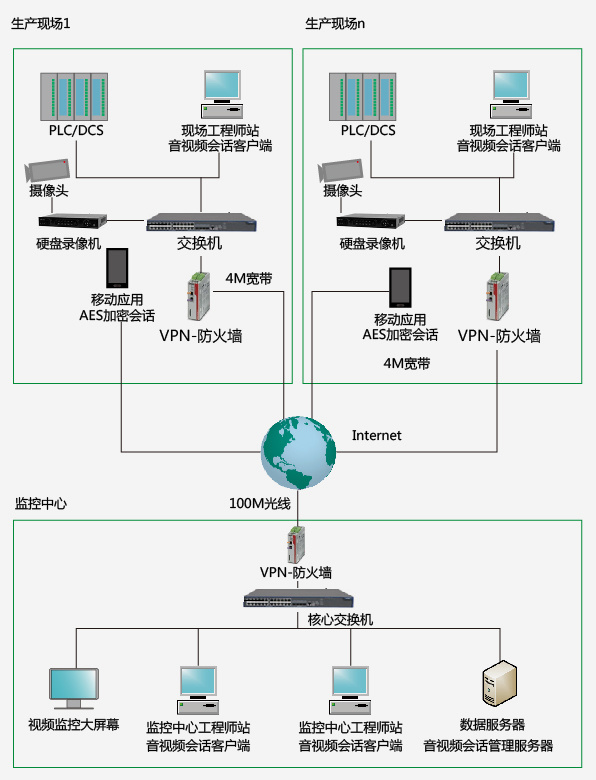

2. Architecture of the Plan

3. Features of the Plan

lThe overall solution is an integrated remote monitoring system that combines monitoring configuration operation, real-time data storage, alarm data query and analysis, and system maintenance.

lIt can collect process parameters, electrical parameters, equipment operational status, and important environmental parameters from hundreds of systems worldwide.

lThe system is divided by region, with each area dynamically displaying online status, operational status, system parameters, etc., achieving remote monitoring and debugging.

lReal-time display of alarms, historical alarm condition queries, and custom settings and additions for new alarms are implemented.

lRealization based on EEMUA 191and ISA 18.2 international standards for alarm analysis functions.

lAlarm and other information can be automatically sent via SMS or email and customized for sending.

lLong-term storage of on-site data, organized and analyzed to provide reference for process optimization.

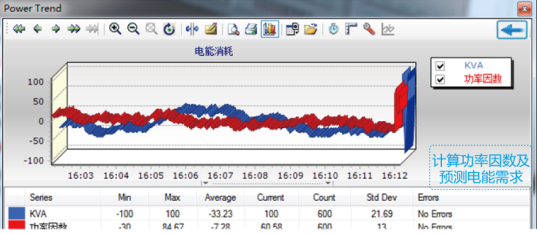

lStatistical analysis of key data such as equipment operating time, energy consumption, and output to provide reference for improving equipment performance.

lRealization of audio conferencing functions for multi-party meetings (using smartphones and other devices), recording audio, and achieving remote video monitoring and storage.

lRealization of remote access to the production site via WEBfor equipment diagnosis and debugging from any location.

4. Function Implementation

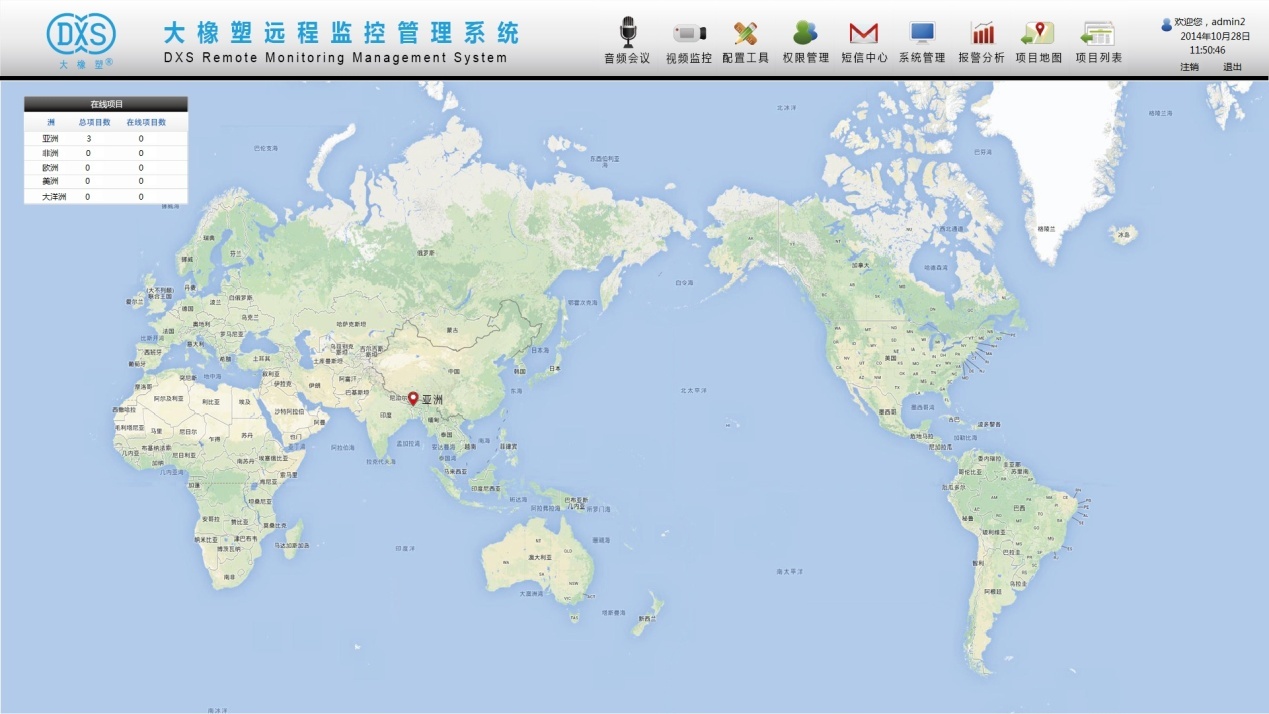

lProject Search

Regions are displayed hierarchically by world, continent, country, and province. Clicking on the red dot indicator on each page opens the next layer. Each layer retrieves macro information such as the number of projects and online projects in real-time, facilitating overall management.

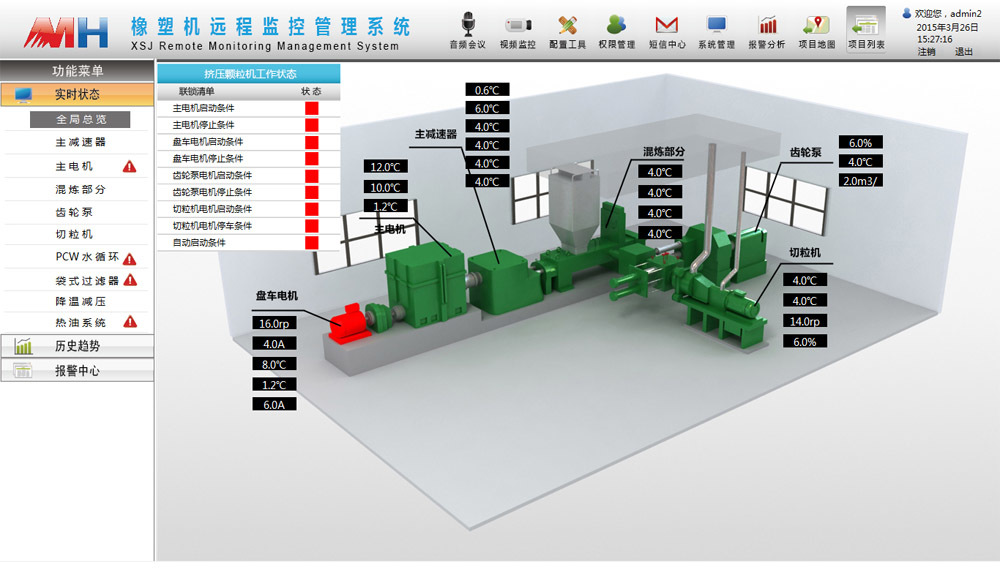

lProcess Monitoring

The monitoring system oversees the entire process. In the monitoring interface, operational parameters such as temperature and pressure can be viewed, as well as real-time alarm information from the equipment.

lHistorical Data Analysis

The system can query trend curves of all collected quantities and also perform custom queries on archived data.

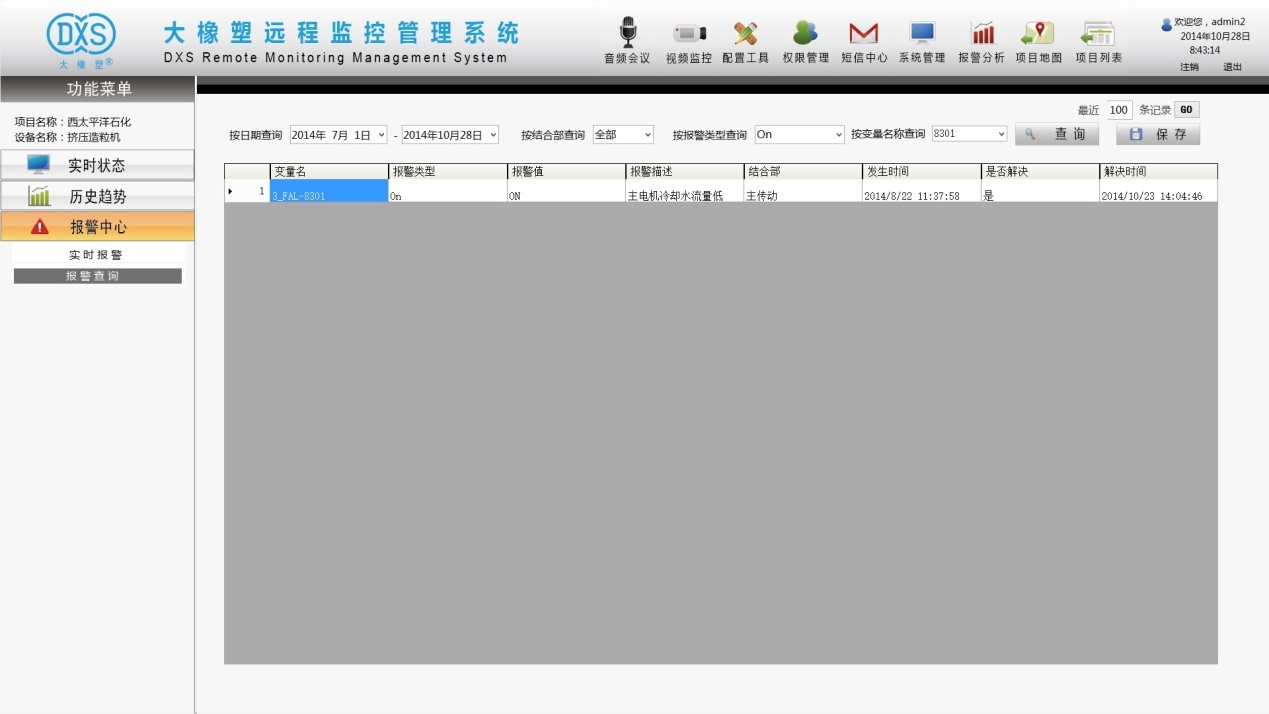

lReal-time and Historical Alarms

The system can display current alarms in real-time and record all alarms, supporting multi-condition historical alarm queries.

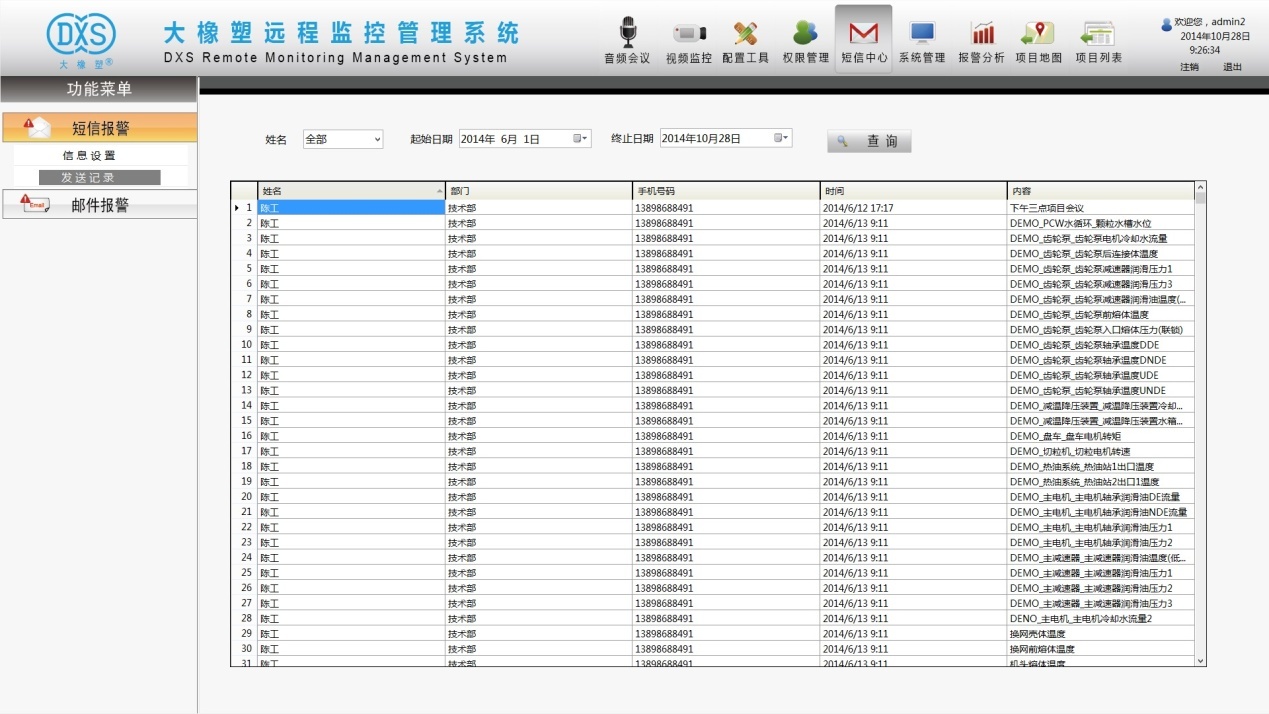

l SMS and Email Management

The system sends alarm information or custom information to selected personnel via SMS and email. It can be configured according to actual projects, setting different responsible persons for different projects or equipment, allowing SMS and emails to be sent to the corresponding project managers, achieving dedicated management for each device and avoiding the confusion caused by numerous alarm messages.

l Alarm Analysis

l Alarm AnalysisThe system can manage and analyze on-site alarm data, including alarm types, frequencies, cycles, times, counts, and locations. For example, alarm analysis can be conducted for a specific location (or multiple locations) within a certain time period, providing specific alarm times, durations, cumulative counts, etc., to make system maintenance targeted and provide a scientific basis for improving system stability and reducing alarm rates..

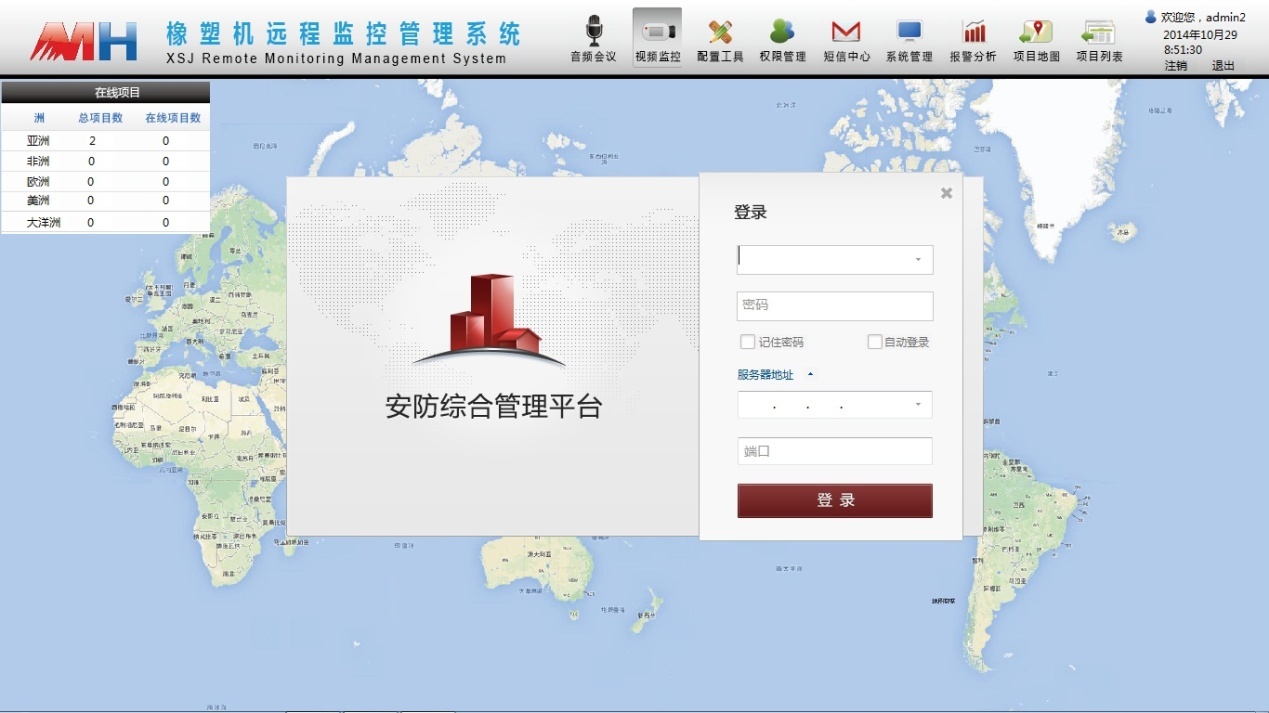

lVideo Monitoring

Remote video monitoring is achieved through a comprehensive security management platform, allowing real-time viewing of images captured by on-site video cameras, and retrieving video information from any monitoring location at any time through a centralized image storage server.

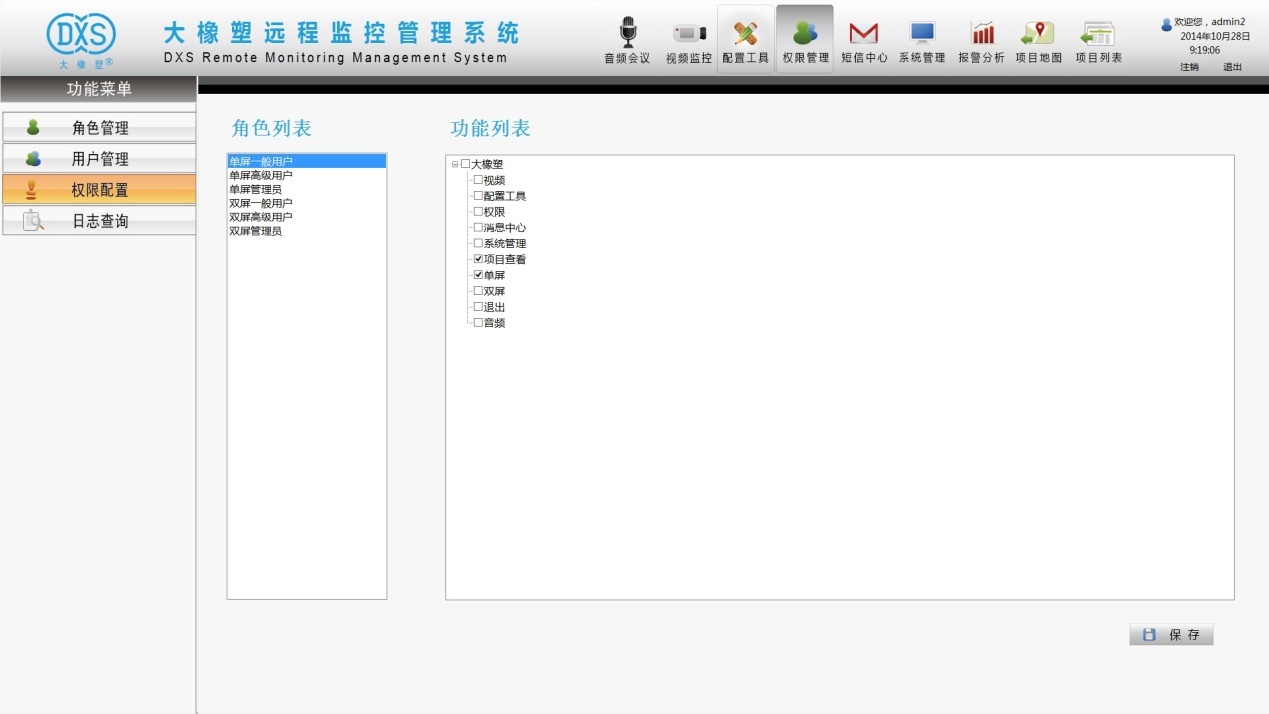

l Permission Management

Functions such as role management, user management, permission configuration, and log queries can be realized. Role management sets members at various permission levels, user management is used to edit user information, permission configuration is for setting access permissions at different levels, and log queries are for checking user operation records.

lMobile Terminals

lMobile TerminalsThe system supports sending job information and alarm information to designated personnel via SMS and WeChat, and also allows remote task assignment via mobile phones, enhancing operational convenience.

5. User Benefits

This system successfully meets the needs for centralized monitoring and management of equipment, while also establishing a close communication channel with customers, responding promptly to customer feedback, enhancing service methods and levels, reducing maintenance costs, and improving maintenance efficiency.

Through further integration of process data, this system can expand big data analysis capabilities, providing a data foundation for process improvements, building an integrated data platform for monitoring, management, analysis, and decision-making, comprehensively optimizing system operation and maintenance, improving safety, production efficiency, and reducing maintenance and personnel costs.