Our story

Here is the title one h1 placeholder text

MHCIMS by Meiheng Company is a crane information solution developed specifically for the safe operation monitoring and comprehensive information management of cranes. It features real-time monitoring, storage, and querying of crane safety information, as well as three main management functions: health management, performance/energy efficiency management, and equipment operation and maintenance management..

A new casting crane at a steel plant in East China has applied our MHCIMS system. During the customer service process, users reported that the crane frequently experienced main contactor disconnection at 5 PM the previous day, and after briefly restoring power, the disconnection fault would occur again, but the fault disappeared after 8 PM..

Our engineers found through historical fault alarm data that—between 5 PM and 6 PM the previous day,5 PMtowithin an hour, the cranereported multiple historical records of overcurrent faults for the main and auxiliary hoists, which aligns with the system design where the main contactor disconnects when overcurrent occurs in the lifting and translation mechanisms..

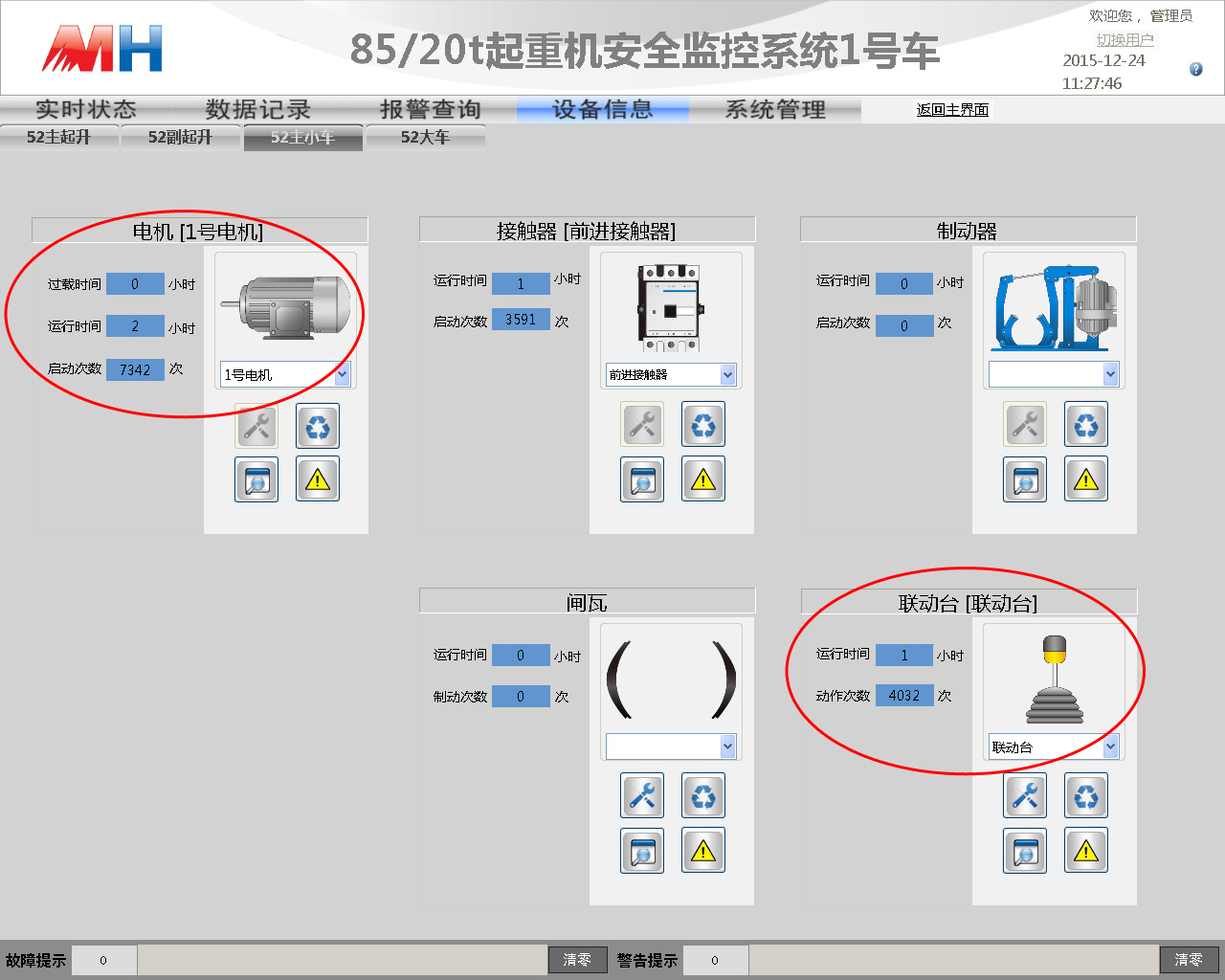

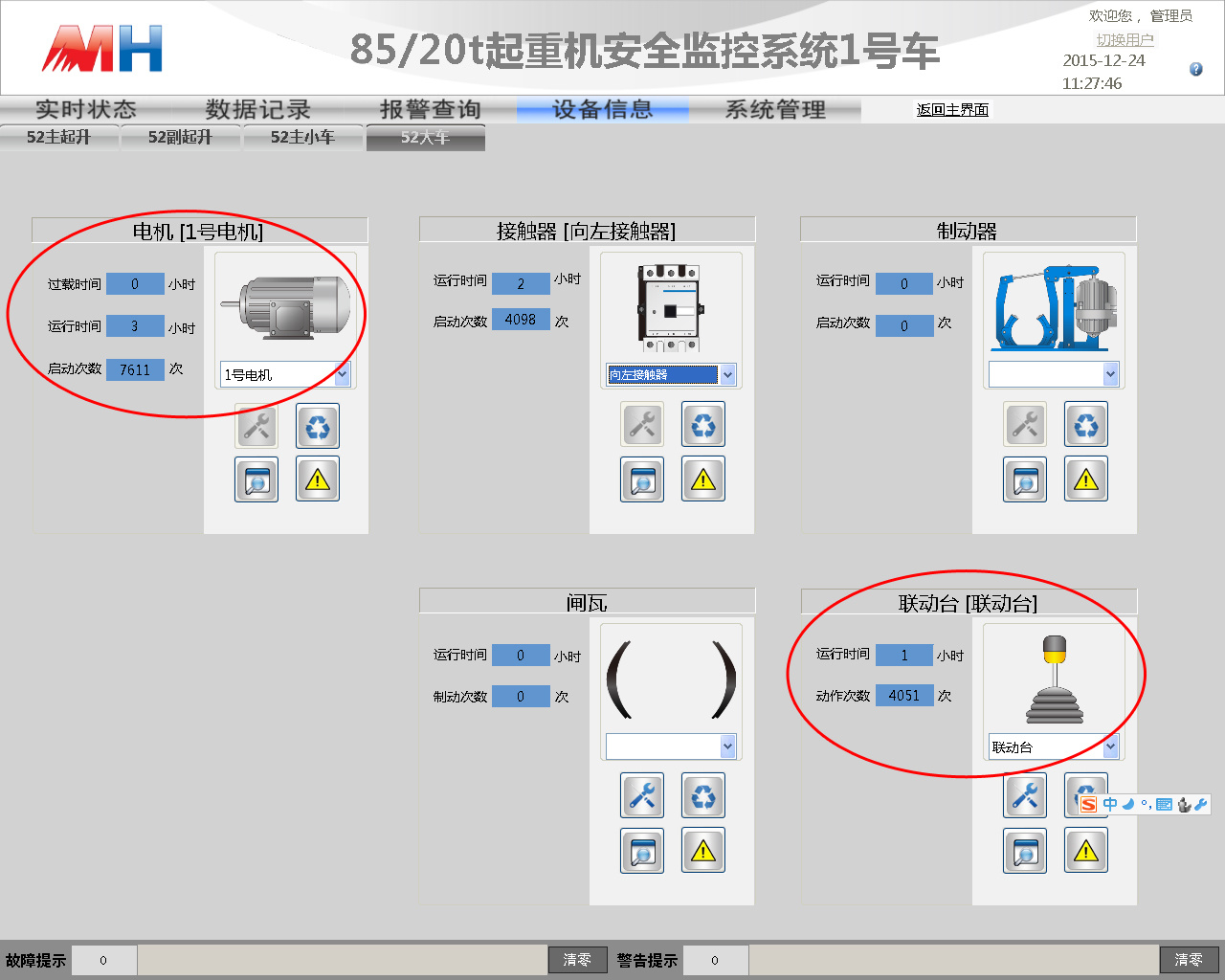

By querying the statistical data from the MHCIMS system, engineers discovered that the action counts of the main and auxiliary hoist linkage and motor start counts had surged abnormally over these two days..

Furthermore, they retrieved the video monitoring records from the driver's cabin during the fault period to understand the driver's response measures. They found that during the 5 PM time period, the shift-changing driver frequently operated the main and auxiliary hoist gear positions, while other drivers during different time periods operated the gear positions smoothly without corresponding faults.

Thus, the cause of the abnormal phenomenon can be basically confirmed: the main and auxiliary hoist mechanisms use traditional resistive control methods, and due to frequent gear operations, the motor starts and rotor resistances are frequently switched, generating large switching currents, which triggered the overcurrent protectors for the main and auxiliary hoists, reporting overcurrent faults. This aligns with the historical fault data from MHCIMS and the fault phenomena reported by on-site maintenance personnel, making it a powerful assistant in discovering and solving various problems..

By suggesting the on-duty driver change their operating methods, this fault phenomenon has not occurred again.

In the comprehensive management and application of cranes, MHCIMS has become a powerful assistant in discovering and solving various problems..

All rights reserved©2025 Meiheng

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.