All categories

Energy Management System Solution

Background

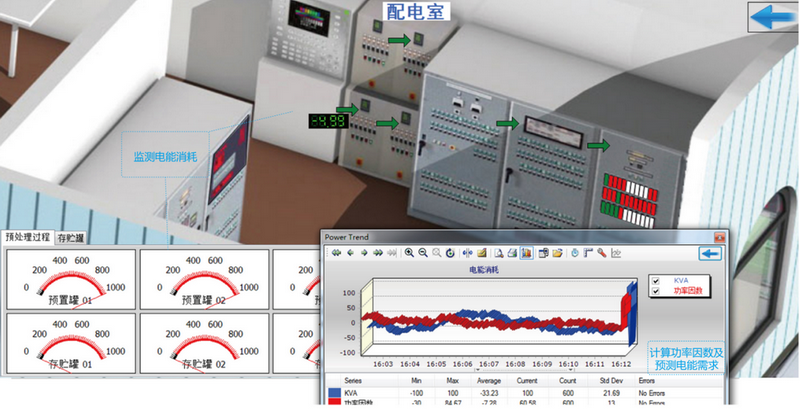

The MH-SCADA based Energy Management System (EMS) is a suite of energy management tools used to monitor, control and optimize the consumption of any factory, building or facility that consumes energy. The EMS control system is designed to reduce and optimize energy consumption and cost, improve the utilization of the system, increase reliability and to predict energy consumption.

System Software Modules

l Energy Monitoring Module

l Energy Network Management Module

l Energy Planning, Scheduling & Management Module

l Energy Device Management Module

l Energy Load Prediction Module

l Energy Economic Operation Module

System Details

Energy Monitoring Module

This Module monitors energy parameters, such as

l Power System’s voltage, current, power, etc.

l Gas supply flow rate, pressure, temperature, etc.

l Water supply flow rate, pressure, temperature, etc.

l Auxiliary systems such as Air conditioners, HVAC, Air compressors etc.

Energy Network Management Module

l Company energy report: used for a companies internal management and analysis.

l Basic unit energy report: is designed for use by different departments or production section management and analysis.

l Energy analysis report: designed to report on energy consumption as a function of production. This report is either time based or quota based and also offers an energy consumption analysis chart amongst other reports.

Energy Planning, Scheduling and Management Module

Based on the automatic or manual energy data collection the system creates thesupply vs demand plan. This allows production managers to use the guiding to produce on the basis of the supply-demand plan so as to ensure there is enough energy for the production line. The supply-demand plan will incorporate water, electric, oil and gas availability. By collecting and arranging the data of the different energy mediums by their availability , consumption and loss bleeding allows users to see the actual mix usage against production allowing management to really understand the energy use by way of an Energy Index.

Energy Device Management Module

This module enables companies to manage the energy consumption of the various assets.This helps the energy management staff to find and sort the key energy consumption assets, to do asset replacement by identifying high energy using obsolete assets and to monitor energy saving assets. This is done by understanding the appropriate data and reports available. Main functions of this module include:

l Company Asset Register Key energy consumption asset register

l Uploading and maintaining company key energy consumption device book

l Production asset register

l Obsolete asset register

l comparison of obsolete assets

In accordance with the register of the outdated and obsolete assetsissued by the State, it is possible tp systematically search the working asset register to monitor and inform when assets reach their end of life.

Energy Load Prediction Module

By analyzing and modelling the historical consumption of all the energy mix against unit production this module can be used to analyse and understand the energy requirements required to achieve a certain required production output. This can assist in accurately pricing the cost of energy per production unit, enabling organisations to plan to ensure there are no shortages or energy or over production of energy that would impact negatively of production costs.

Energy System Economic Operations Module

This module assists in the planning and implementation of energy-saving projects. This includes the planning, approval and to track the implementation and success of any energy saving projects. The module allows the users to monitor any project against a target and allows management intervention along the way to ensure success. When a project is completed this module can be used to monitor the actual energy saving in order to monitor and record the project success and whether it achieved to predicted savings results.

User benefits

Users can use smart meters or a Programmable Logic Controller (PLC) or and Remote Terminal Unit (RTU ) or other devices to automatically gather the energy data that will further reduce the cost of data collection within a facility.

By using the EMS modules including the energy prediction, energy management, energy balance prediction and other functional modules it is possible to scientifically and confidently analyse all of a companies’ energy data with a view to provide a realistic foundation for the company to reduce energy consumption.

It is estimated that by using the EMS Companies could realize an overall energy consumption rduction of anything between 3% to 15%.

Web Copyright:DALIAN MH ELECTRIC LTD. 辽ICP备05006725号-2 Powerby:300.cn dalian